Pallet Racking

Cargo stored on pallet racking has advantages and disadvantages. Though use of pallet racking affords the efficient use of vertical space and rapid movement of large volumes of cargo, users of pallet racking sacrifice the ability to manage cargo at the unit level, instead having to work mostly with palletised cargo.

When managing cargo using pallet racking, pallets should be properly stacked and loaded. Ideally, only like items and/or items with the same SKU will be stored on the same pallet, and pallets containing the same SKUs will be stored next to each other on the same racks. Cartons and cargo on pallets should be uniform and even, with weight evenly distributed across the pallet to avoid accidents while moving using a forklift. Cartons or items on a pallet should also not stick out over the edge of the pallets to maximise the use of space on the rack.

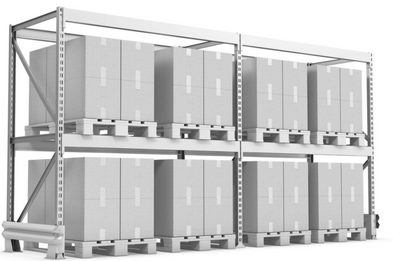

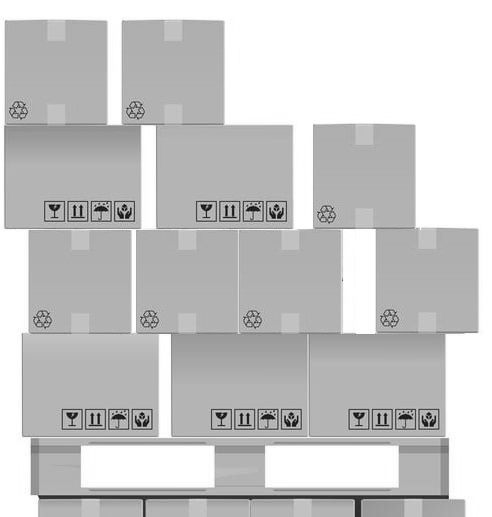

| Improper Palletisation | Proper Palletisation |

|---|---|

|  |

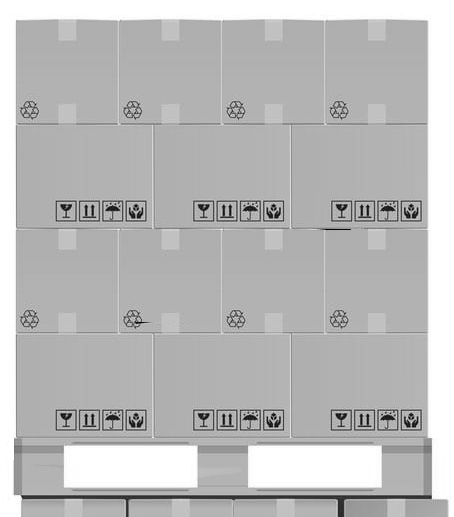

Ideally, pallets should also be well wrapped to prevent slumping or falling during movement and long-term storage. Pallet wrapping is cheap and widely used, and can be done by hand without the need for special equipment. Some products and warehouses also choose to utilised binding – synthetic or organic ropes or straps - that keep palletised cargo together. Properly wrapped or bound pallets will dramatically increase the longevity of the pallet.

| Pallet with Plastic Wrapping | Pallet with Plastic Binding |

|---|---|

|  |

Other general guidance points for utilising pallet racking systems:

- Pallets stored on racks for long periods of time may start to slump or display distress. Pallets appearing compromised must be pulled down, rebuilt/re-stacked and re-wrapped.

- Racks should be numbered for easy reference, including the row number and the level of the racking.

- Items most frequently accessed should be stored in the lower level of pallet racks. More infrequently accessed items should be stored on higher racks.

- Extremely heavy, bulky or expensive items requiring rack storage should be stored on the ground floor of pallet racks to avoid injury while loading or damage to goods.

- Pallets should be clearly labelled denoting consignment information, and should be legible from the ground and at any angle.

- If stock cards are used, they should be kept at ground level in a safely accessible area.

- The rows between racks should be separated far enough to allow for manoeuvring of handling equipment.

- Pallets should be adequate width to sit on the cross beams without risk of falling through.

- Pallets stored next to each other on pallet racks should not come into physical contact.

- Pallets should be evenly balanced across the beam; no pallet should be leaning over the edge of the frame, nor sticking out too far.

- Pallets should not exceed the weight limit of the racking.

- Loading and offloading of racks should only be conducted by a trained professional.

Shelving

Warehoused items stored on shelving offers the quickest and most organised access to the lowest inventory unit. Where as ground stacking or pallet racking are meant for large scale storage of high volumes of items, shelving should be treated as a sorting point for individual items, much like items stored on the shelf a local store.

Shelving is ideal for items that are dispensed at low volumes, such as certain pharmaceuticals or communications equipment, or for high value or sensitive items. Shelved items tend be very detailed, and many individual SKUs can be stored on a single shelf. For this reason, proper accounting is essential.

- Shelved items should have stock cards clearly visible and accessible. If shelved items are taken from a larger consignment in the warehouse, both the warehouse stock and the stock on shelving should probably be tracked on separate stock cards.

- Shelves should not be overloaded, and all items should be clearly identifiable and separated.

- Shelves should be clearly numbered for ease of reference.

As shelving tends to contain loose items or items at the unit level, there are a few tricks warehouse and stock managers can use.

- Fragile items such as glass vials can be stored on the bottom shelf to reduce the risk of accidental breakage if handling units are dropped or fall over.

- Liquids, powders and solids should be clearly separated. Liquids should be stored on bottom shelves, both because of their weight and because a ruptured package might leak on all items below it.

- Some like-items may still need to be separated. As an example - the same quantities and dosage of a single pharmaceutical may have different expiration and/or batch/lot numbers, or different items belong to different donor grants. Each item will need its own stock card and clearly defined space.