In addition to vehicle fleet management, other aspects may be considered when managing a fleet of vehicles. The most pertinent could be the management of special stocks and the environmental impact of the fleet. When managing a fleet of vehicles, it may be useful to stock particular commodities such as fuel and spare parts. The information in this section is complementary to the chapters on sections on physical stock management and on dangerous goods. Rather than focusing in safety issues, the content below is more related to the good conditioning and management of stocks for optimal use:

Self-Managing Fuel

Humanitarian organisations considering managing their own fuel stocks should review the Managing Fuel section of this guide.

Managing Spare Parts

It is important to know when to self-manage a stock of spare parts. The decision is usually linked to the convenience of a self-managed workshop and to the use of owned and standardised fleet of vehicles. Given the complexity, it is not recommended to hold a stock of spare parts if the variety of vehicles in the fleet exceeds two or three different models.

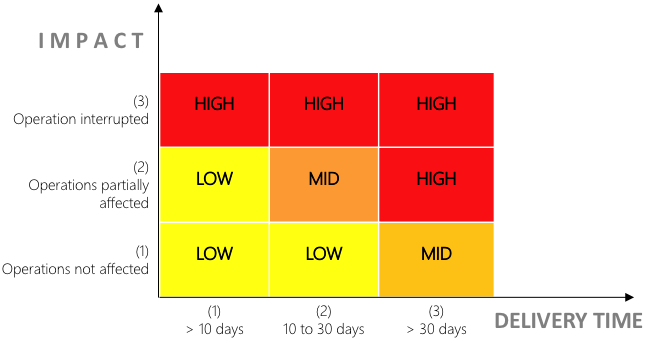

Managing a fleet of self-owned vehicles in contexts where a supply chain remains uncertain imposes a high degree of autonomy in terms of spare parts availability. The risks of not having spares at the wrong moment must be assessed. The following matrix can be adapted and used as guidance for decision taking.

Also consider the reliability of local markets: the cost of original parts purchased locally can be double or even triple that of buying internationally. Generally, most of the parts available locally consist of high demand parts such as filters or brake linings, while less demanded parts may be less available but just as important. Some consumables - such as lubricants and tires - can be easily found locally.

It is recommended to perform market research with a comprehensive list of parts and carefully assess the quality of available parts and validate suppliers. Original quality supplies should be always demanded as the consequences of using counterfeit or substandard parts can seriously affect the condition of the vehicle and jeopardise rider safety.

Once organisations decide to hold a stock of spare parts, they should define the type and quantities of each part required. This can be calculated based on the scale of the fleet, the frequency and types of the preventative maintenance services and the average number of kilometres completed per month per vehicle.

Managing Environmental Impact

Logistics teams must guarantee an efficient use of resources, optimising costs and reducing the environmental impact of movements.

Movement planners should look for opportunities to combine, or in some cases avoid travel. Fleet managers should try to reduce the size of the fleet or replace vehicles with smaller, cheaper and more efficient ones wherever possible. Pooling logistics resources, such as vehicles, with other organisations may also provide significant cost and emissions cutbacks through optimised fuel consumption and smaller fleets.

A vehicle's good mechanical condition and proper use will reduce fuel consumption, extend the life of all vehicle parts, avoid unnecessary expenses, and ultimately, reduce environmental impact.