‘A warehouse is a planned space for the storage and handling of goods and material.’ (Fritz Institute)

The overall warehousing needs of a humanitarian organisation are generally specific to the needs of individual response activities and the overall objectives of the organisation itself. Organisations that deal with large volumes of non-perishable goods may need to have multiple warehouses in multiple locations, while organisations that focus on targeted special interventions – such as psychosocial programming – may have very limited need for a detailed warehousing strategy and may choose to procure and deliver directly from vendors as required by the project. Beyond just anticipated volumes of goods, special storage needs will also dictate a warehousing strategy; managing medical commodities requires far more detailed stock management and possibly specialised storage conditions, while durable non-food items (NFIs) may hardly need anything more than basic protection from the elements.

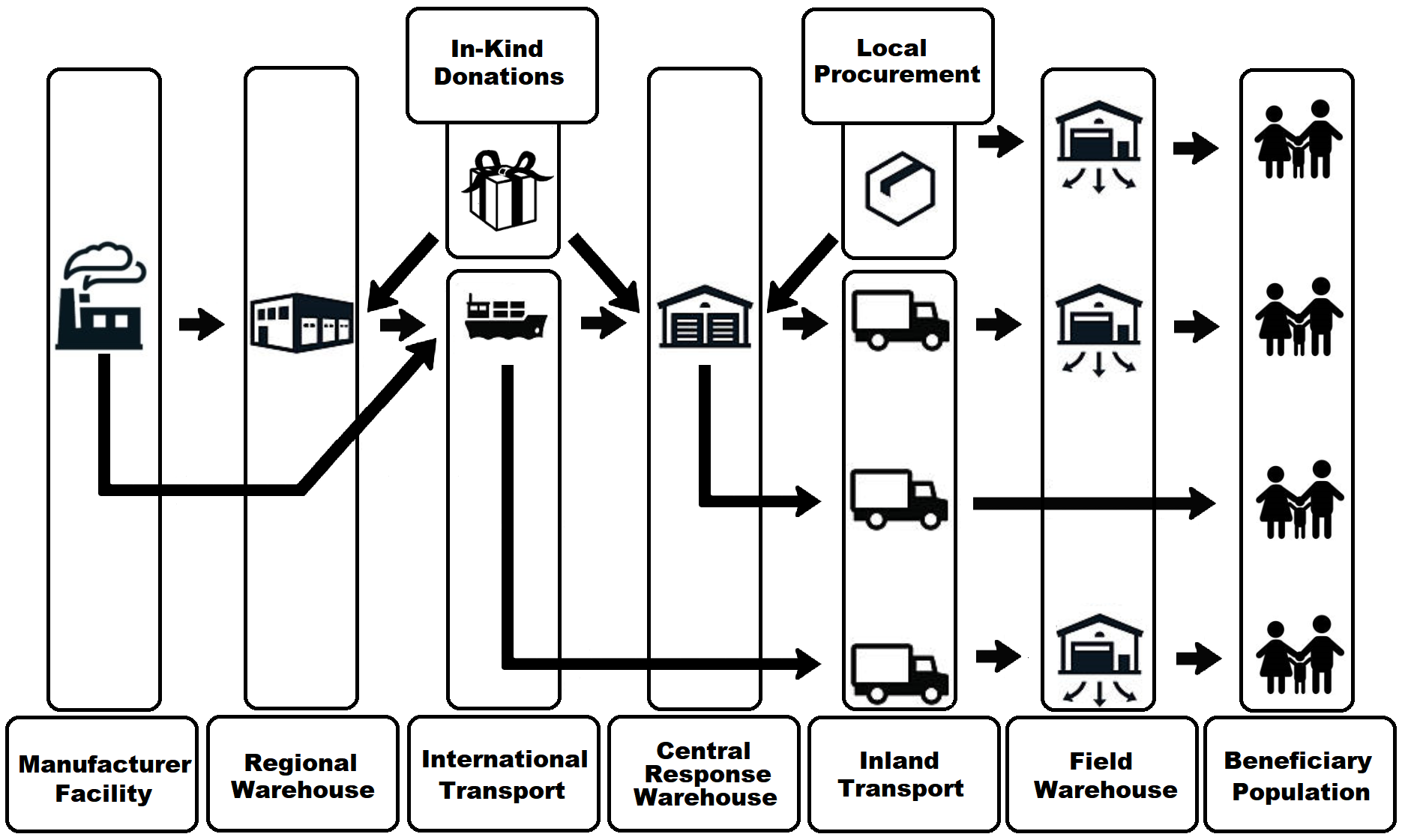

In general, humanitarian aid agency's follow a model for delivering goods to affected beneficiary populations similar to commercial distribution networks, comprised of international and local warehouse facilities that serve as consolidation points, feeder facilities and last mile distribution points.

Example: Overview of a general humanitarian supply chain and warehousing needs.

Regional/International Warehouses

Many international humanitarian response organisations have adopted a strategy of pre-positioning relief supplies in large warehouses not located in the countries of response operation, usually located in one or more strategic regional locations. The development of regional warehouses as lead to a general reduction in time required to respond to rapid-onset emergencies, as well as promotes a more reliable and consistent supply of physical relief items for countries of operation located around the region served by the warehouse.

An international or regional warehouse serves as consolidation point for items as they are received from vendors, donors or partners, enabling humanitarian response organisations to inspect, kit, segregate, repackage, or otherwise prepare cargo for further onward movement. In doing so, regional and international warehouses function as both pre-positioning facilities – holding cargo in case of a rapid unforeseen emergency – and as a feeder facilities – warehouses that slowly resupply warehouses further down the supply chain.

Though many agencies have adopted the regional facility strategy, regional warehouses should not be considered an automatic or default solution. Maintaining a large warehouse - especially one in a remote location not necessarily in the same country as an agencies headquarters – can be quite expensive, and requires additional staffing and time to ensure basic standards are met and the facility properly functions. If an agency is not prepared to commit to paying for multiple years of storage in a remote location, or cannot support the technical oversight or man-hours associated with the proper running of a facility, the agency may choose to completely outsource its regional warehouse management, or forego a regional response warehouse altogether.

Positioning a Regional Warehouse

When deciding on the location of a regional warehouse, the following points should be considered:

- Readily available access to a high volume of intermodal international transport – Is the warehouse near seaports and airports of sufficient size and throughput capacity?

- Relative location to the area of response – Does the region have sufficient response activities and does the location match the overall area of planned intervention?

- The nature of planned interventions – Will the warehouse serve rapid response activities? Or will the warehouse only feed into longer ongoing activities?

- Political climate of the country – Is the government of the country in which the regional warehouse located stable and not prone to conflict, ouster or drastically changing policies?

- Economic feasibility – Is operating in the country cost effective? Are there incentives such as free trade zones or humanitarian exemptions that reduce costs of international operations?

- Access the correct amenities – Does the location have facilities of the right size and quality required? Is there need for climate controlled or bonded storage?

- Access to sufficient technical support – Are there skilled labourers/companies readily available on the market who can manage and conduct special tasks like repairs?

Any of the above mentioned points can have adverse effects on the ability of a regional warehouse to perform its core functions.

Operations of a Regional / International Warehouse

Regional/international warehouses can be purpose built or purpose designed facilities operated by permanent staff that has been trained in all the areas necessary to run an efficient facility, or stock can be held utilising some version of a third-party logistics provider (3PL) staff and facilities. Ideally, any regional or international warehouse would use computer-based inventory management tools, with software to help in the planning and management of the warehouse. The operating environment of a primary regional or international warehouse used for pre-positioning should typically be relatively stable, and overall attention focused on the efficient and cost-effective warehouse operation. Numerous organisations have centralised pre-positioning facilities strategically located globally. Some of these offer extended services to other humanitarian organisations on a cost-plus operating charges basis, such as the United Nations Humanitarian Response Depot (UNHRD) Network.

Central Warehouse – Area of Response

The need and number of warehouses required in an area of response depends on volume and type of activities undertaken and locations of operation. Many response organisations prefer to keep at least one central warehouse in a country or area of response.

A central warehouse in the area of response is typically in either the capital city of the country of response, or in a major commercial hub within the country of response with sufficient infrastructure. The ultimate location of the central warehouse can be anywhere, insofar as it meets the needs of the organisation and the response objectives. In large areas of response, or in large activities, organisations may want a large warehouse in more than one location. The general position of a large central warehouse usually includes its relative proximity to sea and airports, manufacturing facilities, highly skilled or specialised labour or services, and readily available in-country transport services. Central warehouses can be directly managed by the agency, including staffing, rent and security, however in contexts with sufficient commercial activities, a central warehouse may be contracted out to a third-party provider.

The central warehouse serves as the primary reception point for goods flowing into a country, as well as a consolidation point for goods purchased locally. The size of a central warehouse depends on the anticipated volumes of goods themselves, the expected throughput of cargo, and the ancillary activities such as kitting that may occur on site. The overall purpose of a centralised warehouse strategy would be to provide sufficient and controlled flow of relief items to more remote or harder to access locations, keeping enough on hand to meet demand at all times. Some organisations may wish to forego a central warehouse strategy all together in lieu of arranging direct deliveries from vendors or international ports of entry to field warehouses or beneficiary distribution sites.

Field Warehouses

Field level warehouses are another strategy many response organisations have adopted. A field level warehouse is usually towards the end of the supply chain, near the last point of distribution to the beneficiary. Field warehouses can come in a variety of formats, ranging from tents and mobile soft sided structures to small hard sided structures. Some field warehouses might be just as large as a central facility depending on need; what defines a field facility is its proximity to programmatic activities and its role as the last stop en route to beneficiaries.

Field level warehouses usually do not have same level of built up infrastructure as central or international warehouses. Storage conditions at the field level are usually limited at best, and significant improvement might be required for special storage such as temperature-controlled requirements. Security in field level warehouses is also a primary concern, and additional infrastructure such as built up fences and additional guard services may be required. Cargo will likely be moved and stacked by hand with limited storage equipment such as shelving available.

The warehouse work force may be casual labour that has never worked in a warehouse before, while and the inventory system is more likely to be paper based. Often, the situation while setting up a field level warehouse initially chaotic, sometimes dangerous and coupled with a humanitarian need which may be very urgent. The management style must therefore be practical and action oriented with a focus on making the humanitarian goods available as quickly and efficiently as possible, while remaining accountable at the same time.