Temperature Mapping

Temperature mapping is the is process of identifying and marking temperature zones inside of a warehouse used for storage of temperature sensitive commodities, including all anticipated temperature ranges required for storage. Whether or not humanitarian agencies are utilising an outsourced storage facility, or they are managing their own facilities, it is advisable to conduct a temperature mapping exercise so that warehouse managers can best utilise the available space. For more information on evaluating commercial climate-controlled space, reference WHO’s guide on the qualification of temperature-controlled storage areas. For more information on conducting temperature mapping on self-managed spaces, please reference WHO’s guide on temperature mapping of storage areas.

An ideal temperature mapping exercise utilises automatic temperature loggers, however humanitarian organisations might utilise handheld devices such as digital thermometers, or even traditional thermometers. There are several things to consider when conducting a mapping exercise.

Ensure that when the mapping exercise is conducted the warehouse is in same condition as it will ultimately be used to store items as:

- If the warehouse is meant to use air conditioning or other cooling solutions, ensure all temperature controls are enabled and running at the time of the mapping exercise. Note: agencies may wish to map the temperature of the facility without power as well to understand what conditions may be faced in case of a catastrophic power outage

- If the warehouse relies on passive cooling, ensure that conditions match the planned storage conditions, including all shading in place and all doors and windows are closed.

For small storage spaces (single rooms with low ceiling):

- Take a temperature reading at each of the four corners of the storage space.

- If the rooms are longer than four meters, then take a temperature reading along the edges of the floor and ceiling, with readings conducted once every two meters.

For large storage spaces, or locations with high ceilings:

- Take a temperature reading at every two- or three-meter interval both horizontally and vertically. Readings may not necessarily be conducted against a wall or surface – imagine the storage space is filled with invisible cubes of two to three meters in width stacked neatly on top of each other – temperature readings would be conducted at the corners of where each of these cubes intersect.

- If there are wide open areas where no cargo will be stored, it may not be necessary to take a reading – focus on known storage areas such as elevated racking, shelving, and packing/condition areas.

For all storage locations:

- Temperature readings should be recorded into a report or table.

- Temperature readings should be taken at multiple times a day, including in the morning, afternoon and nighttime. Ideally, temperature mapping should also occur during different times of the year, however this may not be possible for a number of practical reasons.

- If there are extreme temperature fluctuations throughout seasons, mapping should be conducted at different times of the year corresponding to seasonal changes.

The outcomes of a mapping exercise will inform how cargo is stored. If there are known areas with significant temperature spikes:

- Managers can be instructed to not store sensitive items in specific areas of the facility.

- Managers can identify potential airflow issues that may be the cause of temperature variations, such as placement of doors.

- Agencies can invest in infrastructure upgrades, such as improved powered cooling equipment or passive cooling techniques such as insulation or shading.

- Planners may choose to simply find another storage facility that is more appropriate for their needs.

Temperature Monitoring

Temperature monitoring is the process of continually monitoring temperature inside of a warehouse or storage facility using some form of recording device. Temperature monitoring can be both automatic, and manual.

All storage locations used to store time temperature sensitive temperature-controlled health commodities – whether they are freezer rooms, cold rooms or regular temperature regulated storages – should have some form continual monitoring of temperature. If there are specialised packing and loading spaces that are dedicated to health items, they should be monitored as well. In high capacity warehouses this can be an alarm based automatic notification when temperature deviates outside of the set range. More likely in a humanitarian environment it will either be tracked with a wall mounted thermometer or handheld thermometer with daily checks. It is recommended that daily checks are taken at different times to identify possible temperature diversions at different times of the day.

It is important to note that temperature monitoring devices (including thermometers, freeze indicators, temperature recorders, alarm systems, event loggers and remote communication devices for monitoring temperatures at all levels of the cold chain) are internationally regulated by WHO PQS. Any use of electronic or automatic temperature monitoring should be done in line manufacturer specifications, including calibration, installation and routine use. Consult the manufacturer and/or qualified installer for more information before attempting to install or calibrate devices without professional support.

Automatic Monitoring

Automated temperature monitoring solutions are considered ideal for storage of temperature sensitive health commodities and should be utilised wherever possible.

Temperature Loggers

| A temperature logger is a standalone device that continuously records temperature on an ongoing basis. Loggers are frequently used while shipping temperature-controlled items, however they may be used to record temperature in remote locations or locations with poor infrastructure. Temperature loggers come in multiple varieties, including those that require persistent connection to external power, and those that can run off battery power for extended periods of time. Battery powered loggers might work for makeshift storage locations in remote areas, however most loggers require data to be downloaded in a proprietary format. This means that on a regular basis or prior to dispatch of the item, the temperature logger would need to be read to ensure no deviation in temperature has occurred. Some temperature loggers are single use, and others are multiple use. Additionally new technology for temperature loggers is always under development. Temperature logger stickers are being used by many humanitarian agencies, readable by mobile phones, with cloud-stored datalogger information. |

|---|---|

| Active Monitoring Devices | Active monitoring devices are specialised equipment that both continually record temperatures and transmit temperature status in real time. Active temperature monitors are ideal in scenarios where temperature regulated items are stored in closed rooms that aren’t accessed all the time, or when more than one temperature control facility is in use, but active monitoring devices can be used in any warehouse where temperature monitoring is required. Active monitors come in a variety of formats, and the way they provide data come in a variety of interfaces. It is advisable that humanitarian agencies interested in using active monitoring devices find devices that:

|

In an ideal setting, active monitor devices should be placed throughout the entire warehouse facility. The WHO Expert Committee on Specifications for Pharmaceutical Preparations suggests that electronic temperature monitors “should be arranged in a grid fashion along the width and length of the area so that the area is reasonably covered, […] located every 5–10 meters.” However, many humanitarian operations function in less than ideal conditions, and the WHO guide on Maintenance of storage facilities indicates correct the correct locations are established in case of limited resources:

- Ambient and controlled ambient storage areas: Position sensors in the places where seasonal hot and cold spots have been observed during the mapping studies.

- Freezer rooms and cold rooms: Position sensors in the places where operational hot and cold spots have been observed during the qualification and/or mapping studies.

The overall layout and number of electronic monitoring devices will depend on the size of the space, and on the resources available to the humanitarian agency. General rules to consider:

| Condition | Ceiling less than 3.5 meters high | Ceiling greater than 3.5 meters high |

|---|---|---|

| Limited number of monitors | Place monitors near the highest part of the wall, approximately 0.5 meters from the ceiling. Repeat at 5-10 meter horizontal intervals. | Place one monitor near the highest part of the wall, approximately 0.5 meters from the ceiling, and then another sensor near the midpoint of the wall, at Repeat at 5-10 meter horizontal intervals. |

| Capacity for multiple sensors | Place one monitor approximately 0.5 meters from the ceiling, and then another at 1.2-1.5 meters from the ground. Repeat at 5-10 meter horizontal intervals. | Place one monitor starting at 1.2-1.5 meters from the ground and add additional sensors every 2 meters up the wall until reaching approximately 0.5 meters from the ceiling. Repeat at 5-10 meter horizontal intervals. |

| Storage facilities with extreme temperature ranges | Consider placing monitors starting at 0.2 meters from the floor if extreme temperature changes are expected. | |

Installation of automatic temperature monitors should take into account alcoves or irregular warehouse shapes. If more monitors are required because of lack of airflow or increased ambient heat in some areas of the facility, consider placing available monitors in those locations over wide-open areas with consistent temperature ranges.

Whatever active monitoring devices are used, ensure that:

- Humanitarian personnel using the devices are fully training in using and reading the equipment.

- The devices are in good working order, and if possible, covered under a warranty.

- Installed by knowledgeable persons. If no person working for the humanitarian organisation is capable of managing the install, utilise an outside service such as the warehouse provider or a private company.

- There is a plan to check on and service the devices at a period defined by the manufacturer.

- The automatic monitoring systems should provide a readout via software or website that is easy to understand, and ideally in a language spoken in the local context.

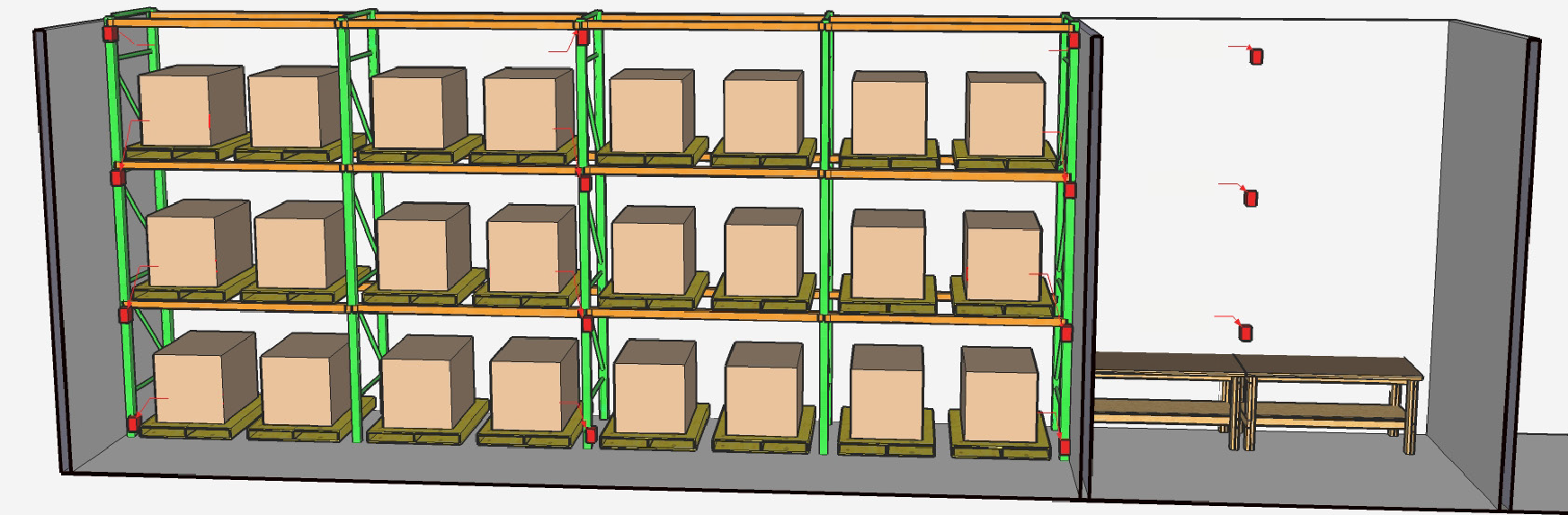

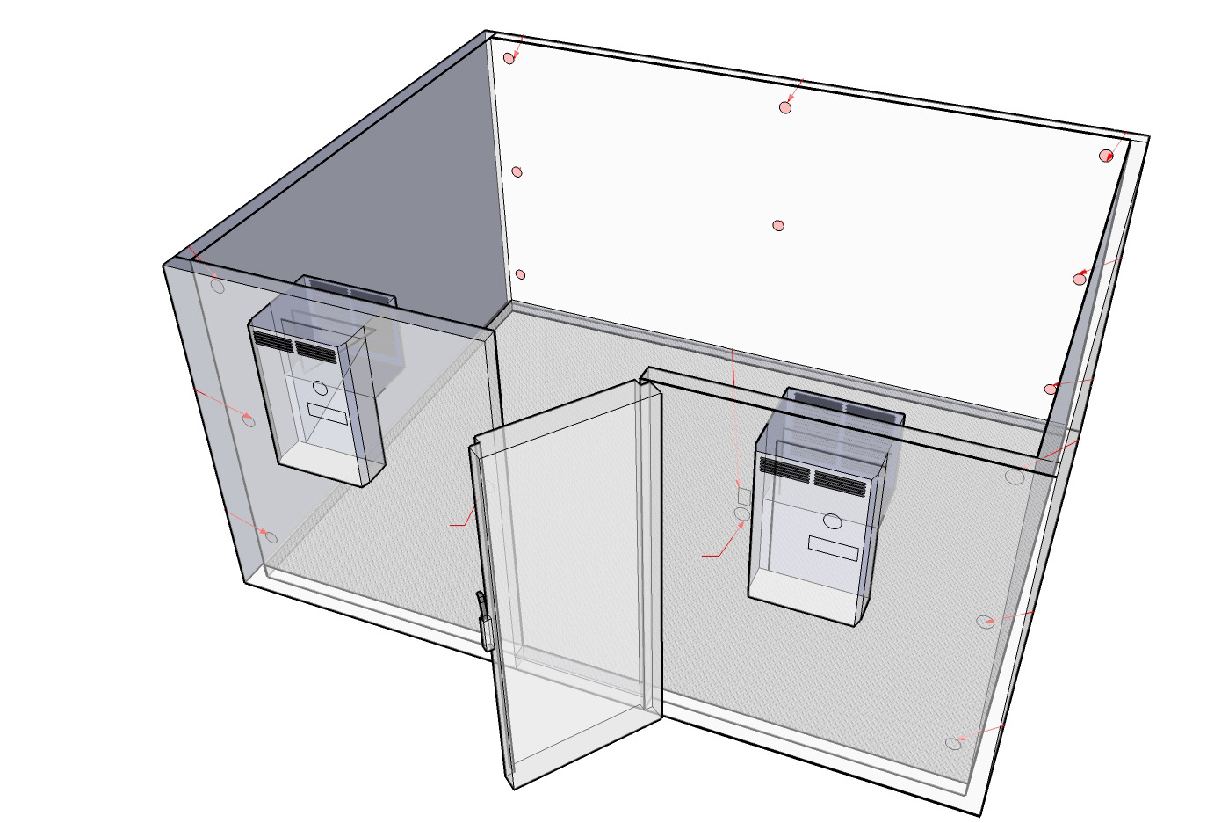

The below arrows indicate the potential locations for temperature monitoring devices.

Temperature monitors in warehouse with elevated storage:

Tempeature monitors in walk-in cold storage room:

Source: WHO - Temperature mapping of storage areas

Manual Monitoring

Manual temperature monitoring of health commodity storage spaces has been practiced for years and was prevalent in most locations until automated monitoring systems became more widely available. Even with advanced monitoring systems, manual monitoring is still used in many humanitarian settings, especially in rural areas, or in areas with heavily impacted infrastructure.

The concepts behind manual monitoring are not dissimilar to those of the automated monitoring systems:

- Self-powered digital, non-digital, or non-powered thermometers can be hung at intervals throughout a climate-controlled storage space and will need to be checked on an ongoing basis.

- Electronic handheld temperature readers can be used to manually check temperature readings in storage locations. This involves holding the manual temperature reader in different locations of the storage facility and recording the temperature at regular time intervals.

Manual temperature monitoring routines are better suited for smaller storage facilities equal to a single room or a small storage site. Attempting to manually track temperatures in large warehouses, or storage facilities with ceilings taller than 3.5 meters may not be feasible.

To facilitate manual monitoring, storekeepers should set a routine, ideally checking two times a day. To make things easier, if there is more than one thermometer in the storage facility, the storekeeper should record the highest temperature found in the room – trying to maintain records on every thermometer may be difficult and confusing. At a minimum each separate space – such as room or dedicated area of the warehouse - should have its own manual monitoring chart. Ideally, in large warehouse rooms multiple manual monitoring charts should be used, particularly if using multiple different active cooling systems, or where one side of the room is more exposed to possible deviations in temperature, such an open loading door.

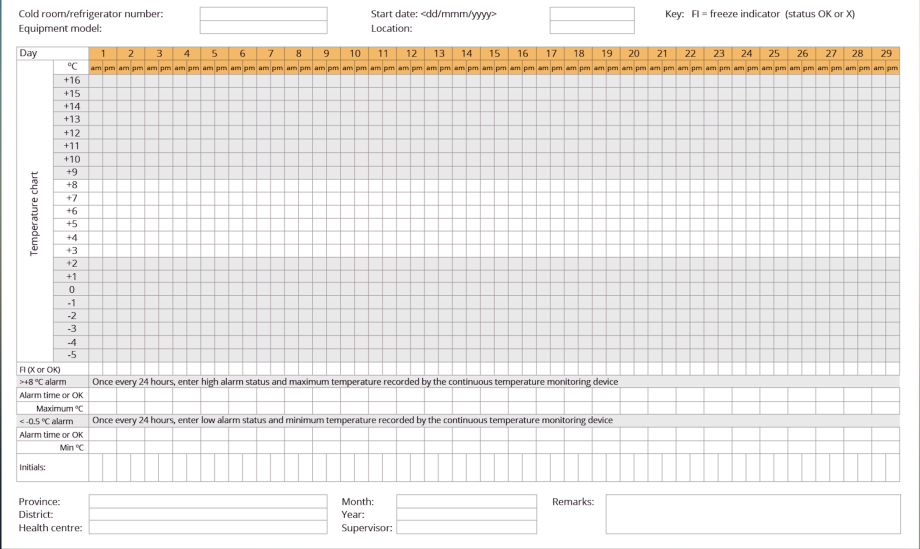

Below is an example manual monitoring chart:

Taken from: Immunizationacademy.com

Once each monitoring chart has been completely filled, it should be backed up in a binder and stored in a safe location – this will enable planners and managers to look at historical trends and identify potential problems with individual storage facilities.