A generator is a combination of an engine (prime mover) that produces mechanical energy from fuel and an electrical generator (alternator) that converts mechanical energy into electricity. These two parts are mounted together to form a single piece of equipment.

Mechanical generators as a source of power are common in the humanitarian sector apart from the public grid, mainly because they are usually available and can be acquired and installed relatively quickly almost everywhere. Generators are built on a well-known technology and it may not be hard to find a good technician to install one in many contexts. However, operating a generator is expensive, requires frequent and complex maintenance as well as a constant fuel supply. Generators can also cause many problems, such as noise, vibration, pollution, and more.

Generators are useful mainly in three types of situations:

- As a main power supply when there is no public electricity grid available or when the grid has a very poor reliability.

- As a back-up power supply when investing in a more efficient power supply is not possible: emergency, short-term installation, etc.

- As a back-up power supply for buildings with very large energy needs (mainly buildings equipped with air-conditioning or electric heaters).

- As a back-up power supply for installations that holds cold chain capacities.

In any other case, a more complete evaluation should be performed to assess alternatives to the generator. When considering a generator as a main or back-up power, do not underestimate the time required for handling the equipment nor to include in the budget the preparation of its installations.

Characteristics

The following are the main characteristics to consider when selecting the appropriate equipment to cover needs.

Generator Power

The first thing to evaluate when looking for a generator is its size - how much power can it generate?

Power rating is standardised as ISO-8528-1. The most common standards are:

| ISO Generator Rating | Load Rating | Run Time Limitations |

|---|---|---|

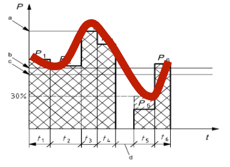

| Prime Rated Power (PRP) | Rated for a variable load | This power is available during unlimited hours of usage with variable load factor. An overload of 10% is possible during maximum 1 hour every 12 hours but not exceeding 25 hours per year. |

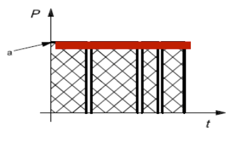

| Continuous Operation Power (COP) | Rated for a constant load | This power is available during unlimited hours of usage with a fixed load factor. No overload allowed. |

| Emergency Stand By Power (ESP) | Rated for a variable load | This power is available only during 25 hours per year with variable load factor. 80% of this power is available during 200 hours per year. No overload allowed. |

Load Types

Most of the time, only PRP is relevant when purchasing a generator. When acquiring a generator, check if the power of the generator is indicated without reference to a standardised rating method. If no rating model is indicated, consult with the manufacturer or obtain documentation from the seller.

Power can be rated either in watt (W), kilowatt (kW), volt-amps (VA) or kilo-volt-amps (kVA). For the sake of clarity, 1kW = 1000W and 1kVA = 1000VA

A rating in watts indicates a real power (P); a rating in volt-amperes indicates an apparent power (S). Only real power has to be considered when planning consumption. Real power is the power actually consumed or utilised in an AC Circuit, and therefore it is the way power needs and energy consumption is calculated in a diagnostic exercise.

If only the apparent power (in kVA) is indicated, you can evaluate the real power with the following general formula:

0.8 of apparent power is the assumed real power factor. This may vary from one machine to another, but 0.8 is a reliable average value.

When selecting a generator, it will at the very least need to accommodate the power calculated in the diagnostic exercise. However take into account the following precautions:

Do not confuse kW and kVA: The installation power needs are commonly calculated in kW while the power of the generator is usually rated in kVA. In that case, divide by 0.8 (or add 20%) to convert the power of the installation from kW to kVA.

| Example: | If the assumed energy needs of an installation are 6,380W, how do we size the generator and what KVA must it be?

The power of the generator must be at least 6.4kW PRP while. To determine the kVA:

A power need of 6,380W requires a generator of a minimum of 8kVa. |

|---|

Take lower operating rates (derates) into account: The power a generator can provide decreases with increases in altitude and temperature. The following chart indicates correlations in environmental factors to derates:

| Altitude | Derate | Temperature | Derate |

|---|---|---|---|

| ≤150m | No derate | ≤30°C | No derate |

| 300m | -1.8% | 35°C | -1.8% |

| 500m | -4.1% | 40°C | -3.6% |

| 1000m | -9.9% | 45°C | -5.4% |

| 2000m | -21.6% | 50°C | -7.3% |

| 3000m | -33.3% | 55°C | -9.1% |

Note that temperature inside the generator room can be far higher than ambient temperature.

| Example: | A generator has an apparent power of 10kVA, and will operate at 1,000m elevation, and in a generator room with an average temperature of 45°C. What will the anticipated power output be:

Elevation adjustment:

Average temperature of 45°C:

The “actual” apparent power is 8.52 kVa. |

|---|

Rotation Per Minute (RPM)

Generators’ engines usually have either:

- 1,500 RPM: intended for intensive usage (running more than 6 hours) capable to reach high power.

- 3,000 RPM: intended for short term usage, with better power/volume and power/weight ratios but higher hourly consumption of fuel.

1500 RPM generators should be preferred by most humanitarian actors.

Noise Level

An engine is very noisy while running. Noise level is an important consideration while looking for a generator, as it is usually running during working or resting hours. A continuous noise even at very low level can become exhausting over long period of time.

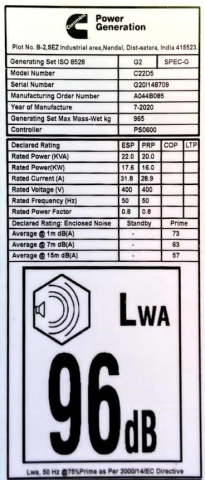

Noise levels are indicated in dB(A) LWA. For comparison purpose here are some common sounds.

| Common Source of Sound | dB(A) Level |

|---|---|

| Refrigerator at 1 m distance | 50 dB(A) |

| Vacuum Cleaner at 5 m distance | 60 dB(A) |

| Main road at 5 m distance | 70 dB(A) |

| High traffic on an expressway at 25 m distance | 80 dB(A) |

| Petrol Lawnmower | 90 dB(A) |

| Jackhammer at 10 m distance | 100 dB(A) |

| Discotheque | 110 dB(A) |

| Threshold of pain | 120 dB(A) |

An average office should be around 70dB(A), while noise level in a bedroom at night should be lower than 50dB(A).

Note that when comparing noise levels at different distances:

- dB(A) @ 4 meters ≈ dB(A) LWA – 20.

- Noise level decreases by 6dB each time the distance from the source doubles.

| Example: | There is a 97 dB(A) LWA generator in a generator room located at 15 meters from a building. What volume will be heard in the building?

97dB(A) LWA is equivalent to 77dB(A) @ 4 meters

The noise level in the building will be approximately 65 dB(A), maybe lower depending on the acoustic isolation of the generator room and the office. This is an acceptable level for an office but not for a guest-house at night. |

|---|

In general, is recommended not to use generators that produce a noise level higher than 97 dB(A) LWA. If the generator will be used at night, it is recommended to use an acoustic canopy, or build a sound wall to dampen some of the noise pollution.

Tank Capacity

A generator cannot be refuelled while it is running, thus the tank capacity is one of the main factors determining autonomy. A conservative estimation of a 1500 RPM generator hourly consumption is 0.15 L x rated power. A fuel tank must be chosen accordingly.

| Example: | An 8kVA PRP generator powers an office without refuelling it during working day (10 hours). Knowing these numbers, what is the suggested tank size?

The hourly fuel consumption of that generator is:

The calculation for the fuel tank is:

Then the fuel tank capacity must be at least 12L |

|---|

It is not recommended to run a tank below 1/5 of its capacity; low tank volumes can draw particles and debris settled on the bottom of the tank into the fuel line, and is potentially dangerous for the engine.

Fuel

Generators – like vehicles - can use either diesel or gasoline, and come with advantages and disadvantages. Diesel generators are more expensive, however diesel is often cheaper than gasoline and diesel generators have better power/volume and power/weight ratios than gasoline generators.

The choice of fuel must be determined according to the local price and availability of both type of fuel. One point to consider is what type of fuel vehicles in the organisations use, using the same fuel for both generators and vehicles can reduce complexities of keeping multiple types of fuel in stock. Safety may also be a concern for very large stock quantities of fuel - diesel fuel also has a significantly higher flash point than gasoline, meaning it will ignite in the open air only above 52°C while gasoline can ignite in below freezing temperatures.

Security

Generators must be equipped with a residual current circuit breaker, so that power surges and short circuits can trip the breaker locally, making it easier to reset and preventing damage from occurring further down the circuit. Additionally, generators usually have a manual breaker/transfer switch to control the connection of electricity to the installed circuit of the office or compound.

Generators should also have an emergency stop button, in case of fire, catastrophic mechanical failures, or other issues. An emergency stop button should be clearly marked. Generators with acoustic canopy should be equipped with an emergency stop push button outside the canopy.

Generator Set Up

Generator Room/Storage Area

Generators generally require a specific place to be domiciled. Unless a generator is specifically designed for mobile applications, generally they do not usually move. A generator’s location has an impact on its functioning and lifespan, and needs to be well planned.

Some generators can be extremely heavy and bulky, and often their location around an office or compound will depend on the ability for mechanical equipment or vehicles to load/offload the full-sized generator.

Generators should be installed on a flat, even surface. Unlike vehicles, generators are not designed to operate on slants or while tilted. A slight slant or grade may cause generators to move slightly over time with vibration or exposure to the elements, which can damage structures and equipment, or make servicing equipment difficult. If a heavy generator moves in an enclosed space with a built-up structure around it, moving by hand may be impossible.

The foundation of wherever a generator is housed should be sufficient to support the generator weight and be electrically neutral. Generators can be extremely heavy, and over time can break down or degrade poor foundations, or even shift in their orientation. Additionally, the vibrations of a running generator can greatly speed up degradation of the foundation or storage area, especially if the generator is not securely fashioned in place – the vibration works like weak but constant jack-hammer.

It is good practice to install some kind of shock absorber to reduce generator vibrations, such as timber or rubber pieces. This helps reduce vibration by slightly raising the equipment, and also help control heat while making the unit easier to inspect and identify leaks.

Depending on the layout of the required operating space, generators may be installed in stand-alone rooms, be housed in some sort of open-sided generator shed, or may be exposed to air. Ideally, generators will have at least a roof or other form of covering above them to protect from rain, snow or excessive direct sunlight, all of which can impact the operation of a generator. Due the size and weight of generators, the shed or room may have to be built after the generator has been delivered, offloaded, and installed.

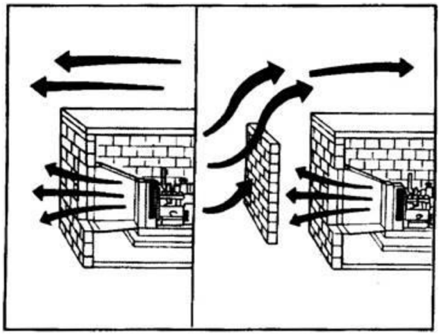

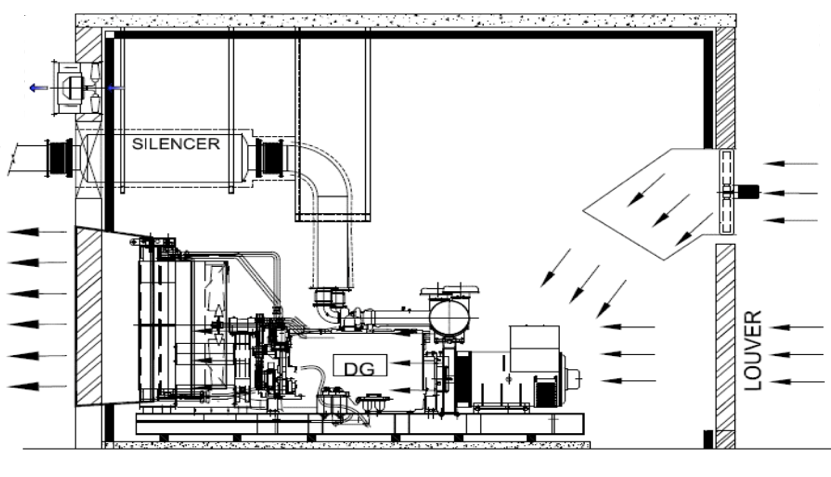

Passive Air Vent Exhaust

Hot Air Output

|  |

Alternate Air Intake

Fresh Air Intake |

The room or storage area must cover several purposes; isolate the generator to decrease the noise and environmental impact on its surroundings, and preventing non-authorised access from staff, visitors, animals, or others. Even if a generator is relatively exposed, such as a covered awning with no walls, it is still advisable to have some sort of access control to the physical generator. The generator’s storage areas may require additional physical built up walls on one or more side of the generator to block noise and prevailing winds.

Although construction materials can vary, the orientation must be planned carefully, taking advantage of the wind currents and minimising the noise and heat disturbances. A generator space should always be well ventilated, including the use of soffit vents or entirely exposed walls. If a generator is in a tightly enclosed space, specially made air outlet ducts are required. Ensure all outlets don’t discharge into areas where humans and animals work or access frequently. If no other option is available than to ventilate into areas where humans and animals access, then all discharge points should be at least two meters from said spaces and be well marked.

Wherever possible, position fuel or other dangerous goods so that the prevailing wind do not enter into the radiator/exhaust outlet. If this is not possible, install a wind barrier.

Running a Generator

While there are general rules and best practices when running a generator, the best source of information is always the user manual for the accompanying machine, which provides full details about its usage and maintenance. Guidance coming from the manufacturer must always be followed.

In general, proper management of a generator starts by having an accurate and up to date monitoring system. Monitoring is crucial for performing analysis, identify potential failures and misuses, and informing future repairs and decision making. It is important to maintain records at least on:

- Running hours.

- Refuelling.

- Maintenance performed.

A simple but complete logbook should be used. A logbook should be kept near the generator, and all persons managing the generator should be trained and sensitised in its correct use.

Even though PRP generator types are rated for “unlimited” usage, this does not mean generators can run for an unlimited continuous time. Generators are still machines, which suffer from degradation and can overheat or break down. The continuous operation of generators may vary from machine to machine, but generally speaking the generators that humanitarian agencies obtain in field contexts are not designed to operate for more than 8 to 12 hours of continuous use at one single time. Running a generator for longer than an 8 to 12 hour period can dramatically shorten the life of a generator and lead to a higher frequency of break downs.

Generators usually must be switched off for a cool down period, which is why many agencies will install two primary generators in a compound or office. The two generators are generally installed near each other if not in the same storage room, and are both connected to the main electrical circuit of the facility. If two generators are installed in tandem, there should be a large external transfer switch to route power coming from either one or the other generator at one time. A no point should both generators be able to supply an electrical current to the same closed circuit at the same time – this could cause catastrophic damage to facilities and equipment.

The use of two generators can be planned according to needs – either both generators should have identical power supplying capability, or the secondary generator is used for hours when load requirements are less. Solar power and other backup power supplies can also be connected to the external transfer switch. Usually, the act of switching between generators includes starting the incoming generator while the outgoing is still running. This will allow the incoming generator to warm up. It will also allow the main transfer switch to move between generators while power is being supplied, to minimise disruption to offices or living quarters.

Starting and Stopping a Generator

Generators above a certain size and made for medium to long term usage generally have an internal switch used to connect or disconnect the unit from the main installed circuit of the office or compound. If the generator switch is set so that the generator is not connected, the motor will still run and the alternator will still produce electricity, however the main circuit will not be able to receive an electrical current.

Generators must never be started or stopped while connected to the installation, also called “loaded”

When a generator turns on, there may be spikes or stalls to the power produced, due to air in the fuel lines, debris or other normal parts of the start-up process. These surges in power can exceed the load rating of any given installation and can damage equipment if not properly protected. It is a good practice to have a poster or leaflet in the language of the persons operating the generator explaining the process to start and stop the equipment that includes photos of the main parts to touch and the actions to be taken.

Standard starting procedure:

- Make sure that the generator circuit breaker is open (if the generator does not have a circuit breaker: make sure that the installation main breaker is open).

- Check the oil level.

- Check the fuel level.

- Check the water level (for water-cooled generators only).

- Make sure that there is no leakage (no oil or fuel under the generator).

- Start the generator.

- Wait 2 minutes.

- Close the circuit to the main circuit of the office or compound.

- Record time of start on the associated logbook.

Standard stopping procedure:

- Warn users that the power will be cut.

- Open the generator circuit breaker (if the generator does not have a circuit breaker: open the installation main breaker).

- Wait 2 minutes and.

- Stop the generator.

- Record time of stoppage on the associated logbook.

- Refuel if necessary.

Care & Maintenance

A generator must be regularly maintained to ensure it provides quality power throughout its life. Routine maintenance is relatively straight forward - there are general guidelines on what and when services are needed to prevent failures or enhance the equipment functioning.

While generator maintenance best practice is following the manufacturer's maintenance and schedule, the following controls and operations can be applied as a close approximation, especially if the manufacturer guidelines are unknown.

| MAINTENANCE OPERATION | MAINTENANCE FREQUENCY | ||||

|---|---|---|---|---|---|

| Daily or every 8 hours | Every Month | Every 150 hours | Every 250 hours | Every 500 hours | |

| General Inspection |  | ||||

| Check Engine Oil & Fuel Level |  | ||||

| Clean and Check Battery |  | ||||

| Check Grounding connection |  | ||||

| Clean Spark Arrester |  | ||||

| Clean Fuel Filters |  | ||||

| Drain fuel Tank |  | ||||

| Change Engine Oil |  | ||||

| Replace Air & Fuel Filter Element |  | ||||

| Clean Engine Cooling Fins |  | ||||

| Replace Spark Plug(s) |  | ||||

| Check fuel injection nozzle |  | ||||

| Replace Fuel Filter |  | ||||

| Adjust Valve Lash |  | ||||

Service hours are tracked in “running hours,” meaning only the hours while the generator is actually on and supplying power. Note that even if running a generator for an average of 12 hours, reaching 250 or 500 hours of total running time can occur extremely quickly, meaning the service intervals for generators can be quite frequent. Small investments made in replacing components and maintaining generators on a regular basis can save expensive and unnecessary upgrades or even replacement of the entire unit in the future.

When performing routine maintenance, each action taken should be logged, as well as the readings and parameters recorded along with the date of inspection and the hour meter reading. These sets of readings are compared with the next set of data collected. Any considerable variation of reading may indicate faulty performance of the unit.

Preventative maintenance thus ensures that the organisation has an uninterrupted power supply for all their needs. If a generator is rarely used, it is essential to start it at least once a week to keep it in good condition.

| Intensive Usage | Occasional Usage | |

|---|---|---|

| Starting generator | As often as required | At least once a week |

| 150 hours maintenance | Every month | Every 4 months |

| 250 hours maintenance | Every 3 month | Every year |

| 500 hours maintenance | Every 6 months | Every 2 years |

Corrective Maintenance

In some programs or sites of operation, it makes sense to have a trained repair technician permanently as part of the team. In most cases, is recommended to identify and establish a long-term agreement or other form of service contract with a trusted provider. Service providers should be in charge of the main maintenance and be ready in case of breakdowns. Important criteria when selecting a third-party provider is their ability to supply spare parts for the required equipment. If a third-party provider cannot supply spare parts, then organisations will need to maintain a stock of their own spare parts.

A generator set is the combination of an engine and an alternator plus wiring, controls, protections and connections. These are the components that need to be checked when looking for a failure.

There are four types of possible generator malfunctions:

- The engine does not start.

- The engine starts, but it stalls or misses.

- The engines works but starts overheating after a while.

- The engine runs smoothly, but the electricity is not properly generated.

It is recommended to refer to the user manual for specific fault-finding instructions as designs vary between manufacturers. Unless a problem is immediately identifiable, a professional generator technician or a qualified electrician may be required.

Safety Considerations

- A generator must never be operated in a room continually occupied by persons or animals.

- A generator room must be correctly ventilated.

- Fuel and oil must not be stored in the generator room.

- A fire extinguisher rated for electric and fuel fires (preferably a CO2 fire extinguisher) must be available outside the generator room. Fire sand bucket can be an option when extinguishers are not available or as a backup.

- All generator must be properly grounded. Usually, generators came with a grounding bolt in the frame marked with the ground symbol, to which ground cables should be attached. If there is no evident bolt, the ground line can directly be connected to the metallic frame of the generator.