Supplier management is a set of principles, processes, and tools that can help organisations maximise supplier relationships, minimise risks, and manage overheads throughout the entire relationship life-cycle. Active supplier management entails creating closer and more collaborative relationships with key suppliers to achieve greater value and reduce risks.

It is important to know specifications of the products or services required, the legal framework for their acquisition and their availability in the market. Not taking these three concepts into account increases the risk of not finding required items, procuring incorrect items, or not respecting local norms and behaviours when purchasing them.

It is important to know specifications of the products or services required, the legal framework for their acquisition and their availability in the market. Not taking these three concepts into account increases the risk of not finding required items, procuring incorrect items, or not respecting local norms and behaviours when purchasing them.

The objectives of an effective supplier relationship management are to:

- Foster long-term relationships and joint value creation.

- Prioritise resources and interaction with suppliers that can provide the greatest value for money.

- Ensure measurement of quality and service levels.

- Develop a consistent mode of interaction with suppliers across the organisation.

- Ensure fairness, integrity and transparency.

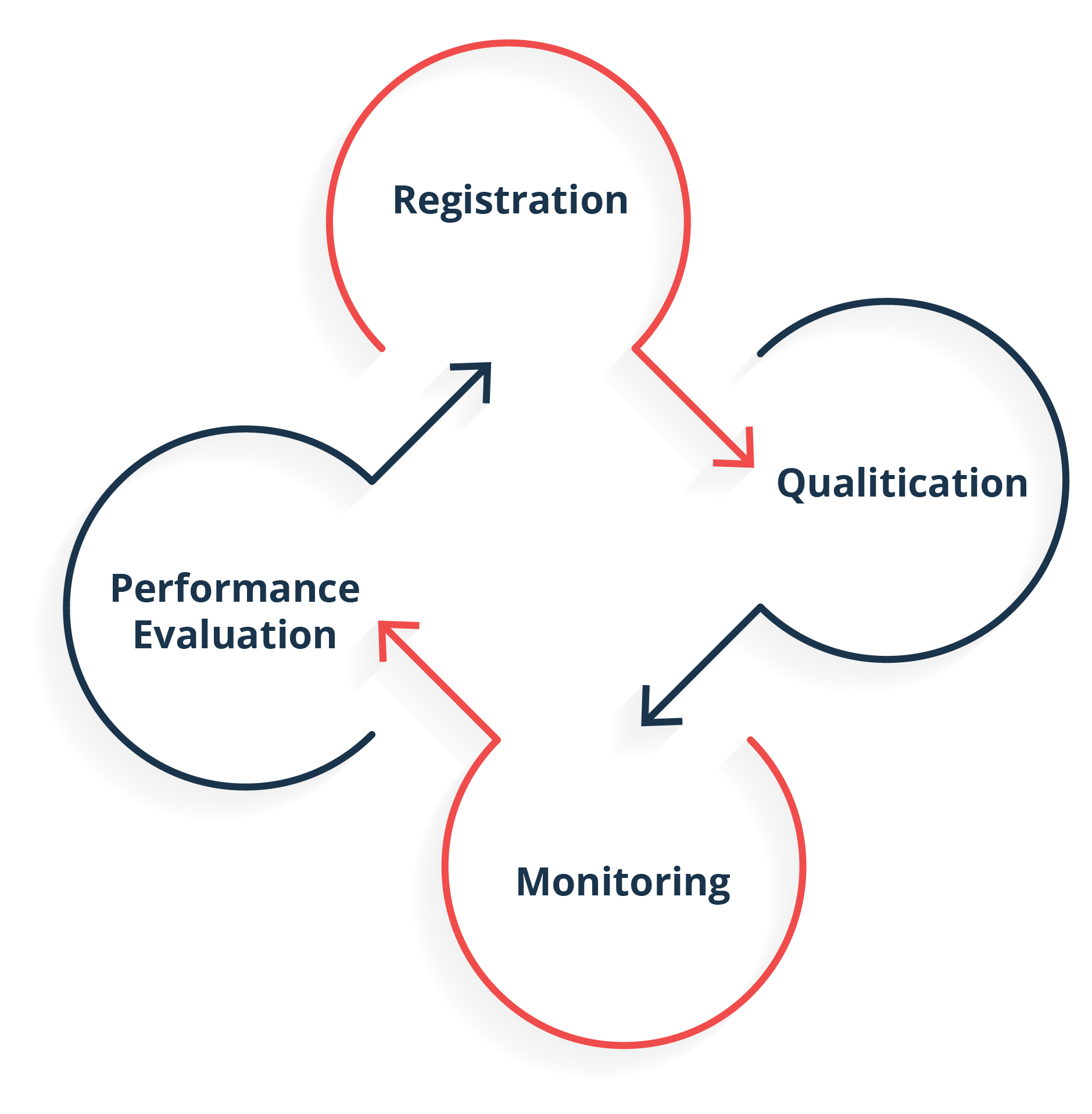

Process

Supplier Registration

It is strongly advised to register suppliers who meet key criteria, including assuring that:

- They have legal personality and legal capacity to enter into a contract.

- They shall have sufficient financial capacity (where required, the last two years audited accounts) to successfully undertake a contract awarded by the organisation.

- The products or services offered must be of interest to the organisation and the supplier must have the necessary professional and technical competence.

- The supplier must not be on any sanctions list and has not performed fraudulent, unethical or illicit acts.

- The supplier shall have the adequate experience.

For certain categories of goods and services, or in certain country specific contexts, suppliers may be required to meet additional/different criteria in order to be registered.

Supplier Catalogue

A supplier catalogue is a tool where every supplier is registered and all the information about their relationship with the purchaser is stored.

| Supplier Pre-Qualification | Pre-Qualification is generally used to pre-select suppliers for the provision of complex/strategic goods and services based on very specific needs. This selection can be from a supplier catalogue or include other providers. Only invited suppliers that meet established criteria should be invited to bid, ensuring that only companies with a high level of quality and/or expertise are included in the solicitation. |

|---|---|

| Supplier Monitoring | Monitoring of supplier activities is most cases done through the standard set of procurement documents. Each procurement step has to be explained and justified and all the official communication has to be documented. It is a best practice to create and update a tool to record key indicators in the procurement process. Such a tool might record of all the interactions with the suppliers allows the agency to analyse and monitor the relations through the time. Key indicators might include, but are not limited to response rates, records of evaluated proposals, number of contracts awarded, POs managed, and expenditures. |

| Supplier Performance Evaluation | Measurement the performance of suppliers in support of an organisation’s needs is important. Historical supplier evaluation influences the identification of supplier who may be short listed in the future. Surveys are an important source of information. The requesting unit should be asked about their opinion about supplier performance in a standardised and official manner. Responses should be included in the supplier catalogue, to be referenced when new procurement actions are being planned. |

Supplier Management Tools

Once supplier(s) are identified, it is useful to:

- Define the exact needs and what you want to negotiate.

- Understand exactly the supplier offer/bid.

- Know your supplier and the market.

- Manage the timelines for delivery of goods and services.

The objective of any negotiation is to achieve a “win to win” situation. If one party in a negotiation does not feel benefited in some way, the relationship tends to break down.

When entering negotiation, it is important to have at least two real possible outcomes to choose from; this will make the negotiation more efficient by having a margin of safety and not feeling/establishing a dependency relationship.

An agreement between the two entities must be formalised, the obligations of each party clearly established, and a mutual understanding of what should be expected from the relationship well understood. There should be well understood steps to take in case of non-compliance to help avoid conflict. The best way to improve working practices in a supply chain is to work hand-in-hand with suppliers to help them to implement achievable improvements.

There are two main tools to manage the relation with a supplier:

- Contract

- Long-Term Agreement (also called Framework Agreement)

Contracts

A contract is an agreement with specific conditions between two or more people or entities in which there is a commitment to do something in exchange for funds. The existence of a contract generally requires the following elements:

- An offer.

- The acceptance of that offer.

- A commitment to carry out.

- A consideration (which may be a promise to pay in some form).

- The moment or the situation in which this commitment has to be carried out.

- The terms and conditions of execution, including the fulfilment of the commitment.

Everything that is worth mentioning must be included in the contract, including the technical quality of the product or service, through the form and conditions of payment, to details about compliance. What is not included in a contract cannot be enforced. It is advisable to dedicate enough time to develop a good contract with mutual agreement with a supplier.

It is advisable to build a contract template, with as fixed a structure as possible, and with simple and direct language. It is common to review the signed contracts to resolve doubts and knowing the structure of our contracts helps to save time. A good practice is to have any contract template reviewed by a local lawyer, who can ensure any contract term is in accordance with the law, and who could advise on local customs and practices.

In the event of any contract dispute, the agency must communicate with the supplier in question. If necessary, a friendly discussion is always preferable. Most conflicts with a provider are resolved with dialogue and the commitment to resolve small details, but this discussion should be formal, including a lawyer if necessary.

Going to court should be avoided whenever possible. Having good contracts that anticipate how possible breaches will be resolved is key. The use of financial penalties is useful during negotiation and a tool in case of conflict.

Long Term Agreements (LTAs)

A Long Term Agreement, known as well as Framework Agreements, establish the commercial terms and conditions that will govern between the supplier and the procuring agency in the event that there is a firm order for the goods or services established in the agreement. An LTA aims to define the commercial conditions that will apply to the purchase of specifically determined goods and for a pre-established period of time. LTAs are especially relevant for small, low-value and less complex items purchased on a regular basis, such as office supplies, most spare parts, cement, prepaid mobile phone service, etc.

An LTA is applicable when several deliveries are expected, but neither specific quantities nor delivery dates can be foreseen. It is important to understand that a LTA is not in itself considered a purchase commitment, but simply sets out the conditions that would apply if the organisation decided to place an order. There is no commitment or exclusivity!

To avoid confusion and possible conflicts, it is essential to make it very clear to suppliers from the beginning of the bidding process that the objective is to sign a LTA and not a regular purchase contract. It is important to ensure that bidders understand the difference between these mechanisms. Since there is no exclusivity, an LTA can be signed with two or three different suppliers of the same products, under identical terms.

There are certain advantages inherent in the LTA that make it useful in any agency purchasing strategy, such as avoiding the repetition of processes and the corresponding paperwork for the same item throughout a project. Being by definition a larger purchase, organisations can get the best product/service at the best price in the shortest amount of time.

As a lasting relationship is established with the supplier, it is possible for agencies to work on the quality of the products/services that they offer to organisations, since agencies will be able to develop the relationship with suppliers to better understand needs and ways of working. In addition, sometimes LTAs are the only way to follow the correct procedures when only a short time is available. Organisations can follow all the procurement process without any requisition, being in a position to respond to requests in less time.