Seaports can be enormous compared to other ports of entry, such as an airport or a border crossing. Seaports must be large enough to accommodate vessels of various sizes, but also can have an extremely large storage and holding capacity. The largest container ports in the world process tens of millions of TEU containers each in a single year. Large ports can be extremely busy, with dozens of ships being loaded and offloaded with specialised cranes and MHE at any given time. Ports also tend to be highly secured and scrutinised – due to the high volume of goods, illegal smuggling and human trafficking have become large concerns for many countries. Based on the sheer size of the operations, vessels may not be able to berth or off load for days or even weeks, instead having to moor off coast waiting for berthing space to open up. It’s also very common for cargo to be delayed while being offloaded and moved around a port, especially in chaotic post emergency periods.

Port limitations can also impact the speed at which cargo can be offloaded, or even prevent offloading at all. Things such as the number of operating cranes, the number of available truck drivers or the available hands to move cargo may lead to significant port congestion. The lack of the appropriate handling equipment can adversely limit a port to the point it cannot service some vessels. In countries or locations with limited or unimproved facilities, it may be impossible to off load certain vessels. Small ports may lack cranes sufficient to move full sized containers or oversized cargo, requiring vessels to carry their own on-board MHE. Even if a port has proper MHE, if the equipment is old, poorly serviced, or the ground operators have limited or poor training, offloading and releasing cargo can be slowed down substantially.

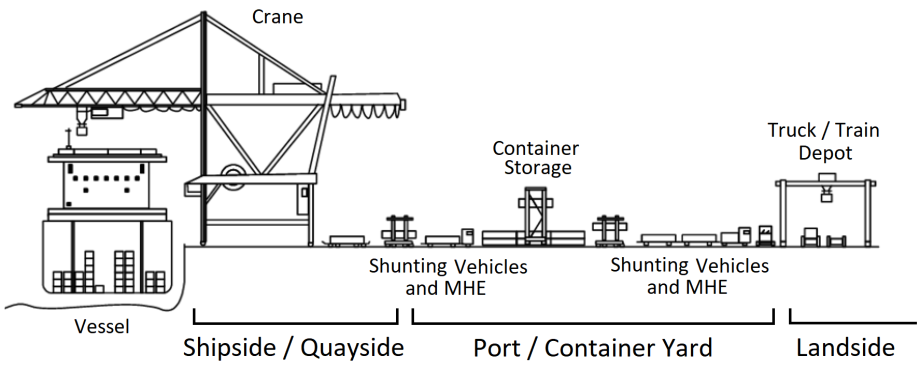

Example Port Operation Overview:

Material Handling Equipment

Ports require specialised equipment to load and offload cargo from vessels. In sea operations, cargo normally arrives containerised, however cargo can also be oversized or bulk. Special equipment is required to properly load and offload items.

Reachstacker - Large vehicle designed to pick up and carry full-sized containers around a container yard. Reachstackers have different sizes, and may have maximum load limits under a fully loaded container. Reachstackers are usually not used for offloading vessels, unless the the vessels are small and in in unimproved port conditions - they are mostly used for rearranging containers in a shipping yard, or loading containers onto truck bodies for onward movement.

Shipside Container Crane - A large crane capable of offloading full-sized containers directly from the deck of a ship. Shipside container cranes may either be stationary, or capable of moving to meet the needs of the operation. The cranes are usually very tall - well above the decks of most vessels rated for that port and are capable of lifting loads up to the max weight of containers.

Gantry Crane - Another form of movable container crane, one that specifically straddles both side of a vessel or stack. Gantry cranes can be large enough to reach over the deck of an entire vessel, but may also be used for loading and offloading trucks or piles of cargo.

Unloader / Grain Vacuum - A specialised tool for offloading loose, bulk cargo such as grain or sand with an extended adjustable arm that reaches into the deck of a bulk carrier. Unloaders can have a mechanical function, scooping and lifting bulk cargo like an elevator inside the arm. There are also configurations where the arm is a giant vacuum for grains called a "grain vac", that pushes loose grain out the back to a pre-set destination.

Ship with Deck Mounted Cranes - Some ships may require their own onboard mounted MHE, such as deck mounted cranes. On-board MHE helps alleviate the problem of working within ports that have limited handling equipment.

Grain Conveyor - A large mechanical conveyor that can either lift and dump grain, or be used to slowly offload grain from the belly of a bulk carrier. If used for offloading, there is usually a bagging operation occurring at the receiving end.