Road Transport Documentation

There is no universal standard to documentation used for cargo shipped by road.

Domestic Truck Movement - In the majority of situations in which aid agencies operate, most cargo movement on roads operates domestically, which doesn’t require international customs clearance. Domestic cargo movement can be tracked in variety of ways, but the most common is a waybill. Many third-party transporters can use their own waybills, however agencies may wish to utilise waybills in their own formats. Organisation specific waybills tend to take specific needs into account, such as accounting for metric tonnage or tracking based on batch/lot number of medication, things which may not be tracked in the waybill provided by a transport company. Shippers are encouraged to use the standard set of shipping documents for all domestic movement.

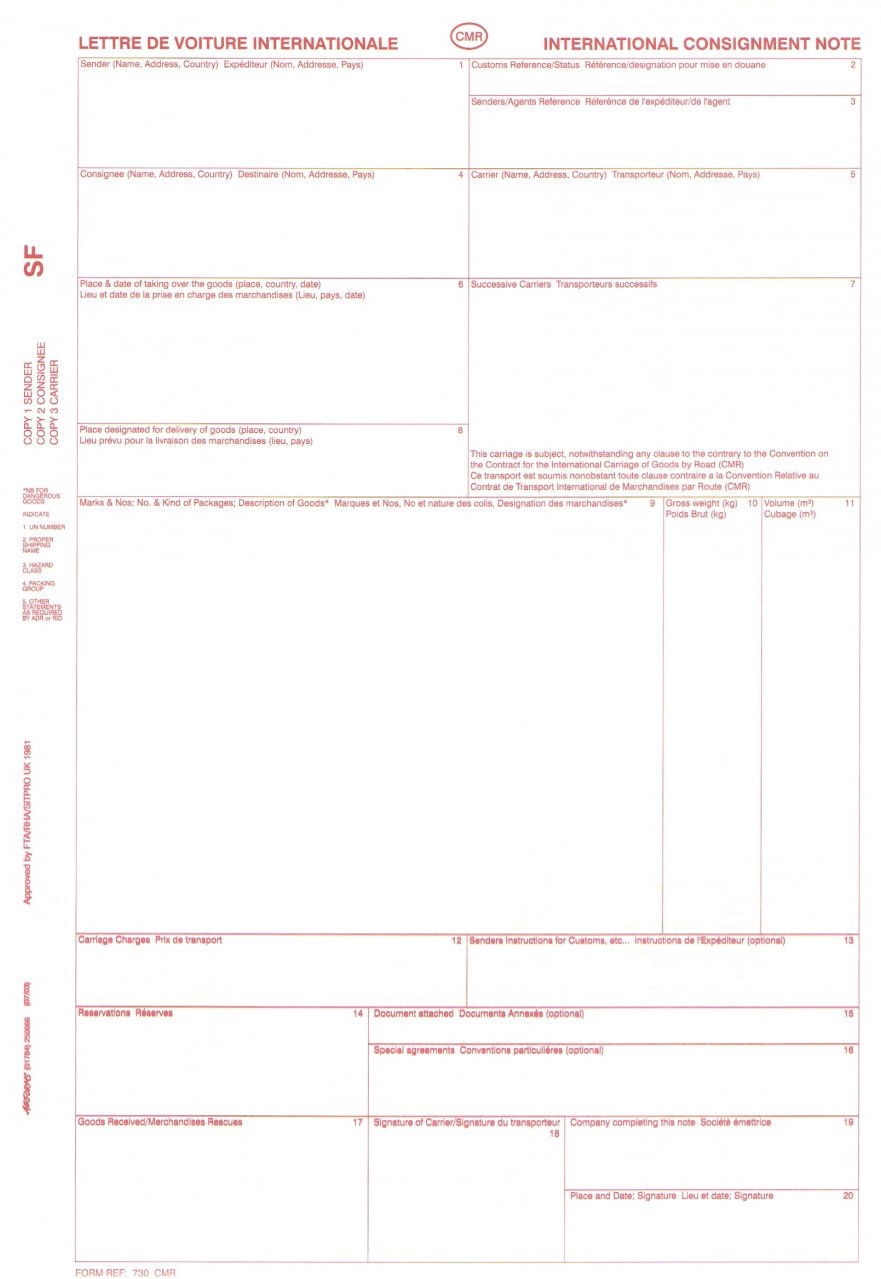

International Truck Movement – Many countries globally recognise what is called a “CMR” international waybill. The CMR was proposed and agreed upon under the United Nations CMR Convention of 1956, and subsequently adopted by the International Road Transport Union. The CMR functions similar to an Airway Bill (AWB) or Bill of Lading (BOL) in that it is a standard and uniformly recognised document for the transport of goods between two countries. Where formally recognised, CMRs are also part of the formal customs process and are asked for by customs officials, and designates roles and responsibilities of parties. The CMR does not take the place of a regular waybill – all traditional documentation may be still be required, and formal customs procedures for importation must be respected – but the CMR standardises the language for authorities to understand the nature of goods either being imported into a country, or across a country. It is important to note that the CMR is not recognised everywhere in the world, there are currently only 45 countries who recognise the CMR, consisting mostly in Europe, the Middle East and Central Asia.

Example CMR:

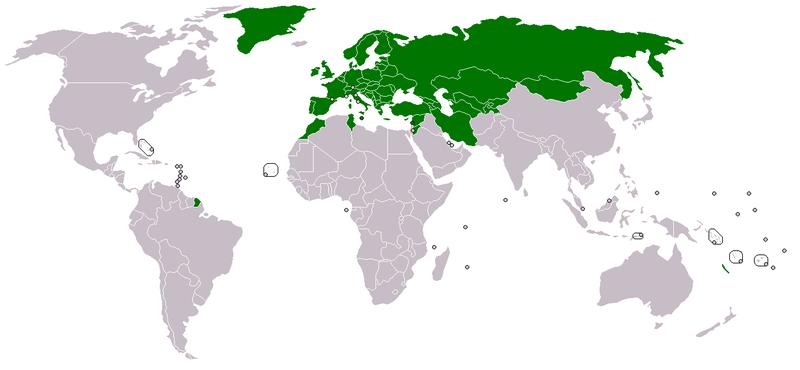

A map of countries that currently recognize and use the CMR in some format:

Source: Wikipedia

Countries who don’t currently utilise the CMR will have their own means of importing cargo, depending on national laws and regional trade arrangements. Prior to importing goods to any country of operation through road transport, shippers and consignees must investigate the import and export laws for both countries.

Unlike air and sea freight which can pass over or around countries relatively unnoticed, many international shipments using trucking will be required to pass through the territory of one or more additional countries to reach their destination. In order to facilitate this process, vehicles may have to travel with what is called a “through bill of lading.” The through bill of lading should contain the relevant information required by the countries through which the vehicle is passing. Vehicles transiting through third-countries may also be subject to enhance scrutiny and inspection, or be required to take additional security protocols to ensure cargo does not enter the local market without undergoing customs. In some cases, banned substances will not be allowed to pass through a country’s national borders at all, even if the final destination is another country.

Occasionally, national laws and the policies of individual transport companies prohibit trucks from crossing borders all together. To mitigate this problem, many states of adopted pre-defined transshipping points at specific places along their borders. At these points, cargo can be offloaded and placed in temporary storage, or even transloaded directly to another vehicle. When this border transshipment occurs, all relevant documentation will still travel with the cargo.

Route Planning and Scheduling

Route planning is the process of planning the movement of a particular quantity of goods in vehicles of known capacity. It assumes that goods are supplied from a fixed depot or starting point and that the location of individual customers is known. It recognises that restrictions on vehicle operations do occur, due to such factors as constraints on working hours, safety and security constraints, the total length of daily travel possible and the volume that can be moved within a normal working day. An acceptable solution to the route planning and vehicle-scheduling challenge should provide optimum routes that satisfy the demands of the work load, take account of legal requirements and reflect the efficient and cost effective use of the operator’s resources.

A satisfactory solution should provide a schedule of routes that minimise either total distance or time travelled by vehicles. Route planning involves an assessing all possible routes, applying the following operational conditions:

- The number of calls to a particular delivery point in any single day is limited.

- The total vehicle travel in any day is limited and the driver's time is limited.

- Vehicles have a fixed carrying capacity.

- Whether the roads are suitable for the specific transport needs and vehicle, including road conditions, hairpin turns, and any narrow gates or physical structures.

- Volume of goods for each delivery point is known and each drop has a location for which there is an established driving time to and from the warehouse or to the next delivery point.

- The quantity of goods delivered to any drop is smaller than the vehicle’s carrying capacity and there is an established time to deliver/collect at the drop point.

- The operating hours of the delivery/offloading points are known, and constraints such as peak hours are understood.

Calculating a Route Plan

A vehicle route is scheduled by basic following steps:

- Establish the time it takes for a vehicle to travel from the origin to a delivery point, adding the time taken to offload at the delivery point, assuming the vehicle is not over capacity or operating at unsafe speeds.

- Establish geographic proximity from the first delivery point to the second (if more than one delivery), counting total time to arrive and any offloading time, also assuming the vehicle is not overloaded or travelling at unsafe speeds.

- Repeat for all desired delivery points.

Continue this set of assumptions for all delivery points needed – once the theoretical vehicle is either too full to carry all deliveries, or the vehicle cannot complete all deliveries during safe and normal hours of operation, then you have established a route plan that fully utilises the available driver's time or the vehicle capacity. Repeat this step for as many vehicles until all orders are allocated or all available vehicles are fully loaded. When calculating the driving time it is important to use an average speed relative to the vehicle type, quality and condition of the roads, and prevailing weather conditions allowing for such things as delays at junctions, hills and urban congestion. In practice, average speed will be considerably less than the maximum permitted speed for a road.

The nature of the movement can be split into two basic types:

- Primary Movement - Involve typically bulk movements between two specific locations. This may be between two warehouses in a network or from a port or rail-head to a warehouse.

- Secondary Distribution - Movements that may involve multiple deliveries within a defined area, such as a regional or local warehouse to extended delivery points.

In both cases, the emphasis is on achieving full utilisation of the resources used - filling the vehicle to capacity minimising the distance travelled and optimising the hours which the driver is being paid to work.

Safety and Security

There are a number of safety considerations when planning and managing road cargo, these might include:

Load Securing – Ideally, cargo will be properly secured. A secured load does not just mean sealed to prevent theft, but also to prevent cargo from falling off, or worse, vehicles tipping over and causing accidents. Hard sided box trucks should be properly locked, while intermodal containers may be officially sealed depending on the delivery terms. Cargo stored on flat bed trucks or trailer should be properly tied down and covered. At minimum, cargo should not move around inside or on the truck surface as the vehicle moves, and there should be no spillage or falling items on the road causing hazards for people and other drivers. Local regulations might also govern things such as the vehicle weight, the way it is loaded and how the load is distributed.

Loader/Porter Safety - The process of loading and offloading trucks can be very dangerous. Flatbed, box or drop side vehicles may be loaded with the assistance of machinery such as forklifts or small cranes, both of which may move excessively heavy loads that can fall and injure bystanders. The area around trucks loaded with MHE should be cleared of unnecessary personnel, and any designated persons should be clearly marked with high visibility vests.

In humanitarian field settings, vehicles are often loaded by hand, frequently by low skilled labour. Porters should be able to safely and ergonomically load cargo onto vehicles:

- Porters should not carry cargo of excessive bulkiness or weight.

- If the loading point does not have a drive up loading bay, porters should be able to safely step up and down from the vehicle bed without jumping or climbing.

- Porters should only be expected to load for reasonable amounts of time, with breaks in between. Ideally loading teams would be split; 2-4 loaders on the truck and the necessary number of loaders carrying goods to and from the warehouse/depot/discharge point, reducing the need to enter or exit the vehicle.

- Porters should be monitored for unsafe behaviour or possible security concerns.

Road Conditions – In many humanitarian contexts, road conditions are extremely poor. Vehicles should be well maintained as possible, and drivers should not take unnecessary risks. Trucking on poor road conditions such as mud, loose soil or standing water can be augmented by the use of 6x6 trucks (3 axle vehicles will all wheel drive) or any vehicle with a drive shaft that powers the rear axles. Drivers should also understand the route, and have some experience navigating adverse driving conditions.

Infrastructure – In the immediate aftermath of a rapid onset emergency, or as a result of armed conflict, infrastructure such as roads and bridges may be fully or partially damaged. Routes that may have been previously accessible may be inaccessible. Third-party transport companies and hired drivers should exercise caution around damaged infrastructure.

Transporting Dangerous Goods - Vehicles transporting any amount of dangerous goods (DG) for any reason should reference guidance on the road transport of DG in the Dangerous Goods section of this guide.

Vehicle Marking – Depending on the context, there may be national and local laws that require vehicles containing specialty items such as livestock or any form of DG items to be properly labelled and marked while on the road.

Driver Behaviour – Drivers and operators of vehicles are responsible for using a vehicle on the road with a safe and secure load. Local laws will often state that the drivers in transit have full responsibility for the safety of their load, even if they did not load it personally. Even in countries or local contexts where such laws are present but are not implemented, respected or followed, every effort must be made to ensure that the organisation’s drivers are following the regulations that have been established. Most humanitarian organisations also have their own safety and security policies that need to be followed.

In-transit Theft – The main sources of vehicle theft are from depots, from overnight parking areas and from the roadside. Theft can be committed by stealing an unattended vehicle, forcibly hi-jacking a vehicle, or bribing drivers. Drivers are central to prevention of this type of loss, and their integrity is essential. Consequently, careful recruitment and selection of drivers is critical. Training will impress upon them the need for care, and procedures to follow to avoid risk of theft. Driver identification cards can be used for added security and to avoid thieves gaining access to vehicles by misrepresentation when parked on third party premises. However, there is little to prevent deliberate collusion by drivers. Vigilance is essential and attention to any pattern of discrepancies on loads. A thief intending to steal a loaded vehicle benefits from:

- Knowledge of an attractive load.

- The opportunity to access it.

- Time to steal it and to get away before detection.

- A market for the goods.

- Limited or negligible perception of risk.

Vehicle Recovery

In the process of movement by vehicles in austere working conditions, vehicles can and will break down, become stuck, or otherwise be immobilised. Understanding they types of equipment and techniques used to recover vehicles is important to drivers and persons planning routes, while knowing the route and type of vehicle in use will help inform the type of recovery tools. Some recovery tools are extremely dangerous when in use, and should be operate only by knowledgeable persons with proper training! Some of the below recovery items are useful for recovering light vehicles only. Heavy vehicles exceeding 7-10 ton capacity may require additional special assistance.

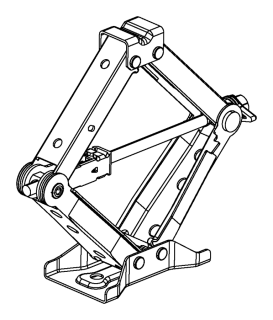

Scissor/Bottle Jack – Scissor or bottle jacks are regular vehicle jacks that might be part of the standard package of tools that new cars come with. Scissor or bottle jacks are useful for changing single tires, but are really only best suited for flat, stable road conditions. Scissor/bottle jacks may not work well in mud, and can really only be used to elevate the vehicle enough to change a single tire. On non-paved roads, they may require a solid object underneath them to distribute the weight, such as a flat rock or a strong board. Scissor/Bottle jacks should only be used on the appropriate contact points to avoid causing damage to the vehicle.

High-lift Jack – High-lift jacks are far more robust than scissor/bottle jacks. They can be used to lift vehicles out of mud, or raise vehicles enough to place braces or other objects underneath them. When a vehicle is full lifted, a supporting high-lift jack can have enormous pressure on it; the jack handle if not properly secured can cause bodily harm, and the jack itself may collapse with the full weight of the elevated vehicle. High-lift jacks should only be used on the appropriate contact points to avoid causing damage to the vehicle.

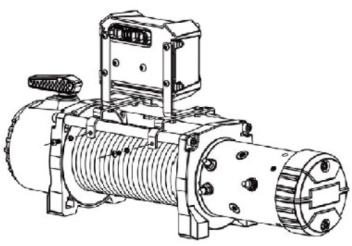

Recovery Winch – Recovery winches are powered electric motors that can retract rope or metal cable. Many field level vehicles have winches permanently attached to the vehicle, usually on the front bumpers. Winches usually draw their power from the electric battery of the vehicle, and are capable of supporting the weight of the vehicle itself. Winches should only be attached to objects and anchor points that can physically support the weight of the vehicle and withstand the horizontal pressure applied by the winch. When a winch is being used, all persons should be inside a vehicle, have proper cover or be a safe distance away.

Winches are useful for pulling vehicles stuck in mud, or are otherwise immobilised on an incline. Because winches are made to support the full weight of a vehicle, the cables or ropes can be very dangerous under full pressure. Additionally, improper use of a winch may cause damage to vegetation or nearby structures. Sometimes, vehicles with winches utilise what are called “snatch blocks” or "winch blocks" – pulleys that are designed to change the direct anchor point of a winch when a clean anchor isn’t available.

Snatch Straps – Snatch straps are bands made of durable synthetic material that are designed for one vehicle to pull another vehicle. Snatch straps should be strong enough to support the weight of the vehicle being towed, with some additional tension caused by momentary velocity differences between the vehicle being towed and the vehicle pulling. Snatch straps should only be used in a slow-speed, and only in a recovery capacity. Much like the winching, snatch straps should only be in use when all persons are at a safe distance.

Other tools that may be useful for vehicle of all size include:

- Tire irons

- Full sized spare tires

- External air compressors

- First aid kits

- Jumper cables