Warehousing and Physical Stock Management

Common Terms in Warehousing

|

Stock Keeping Unit (SKU) |

A unique code or nomenclature that designates a single line item of a larger consignment. SKUs may be tied to a specific production run or expiration date, and may denote only a product of specific characteristics. A single storage facility with multiple SKUs will require very different handling procedures than a storage facility with few SKUs. |

|---|---|

|

Inventory Unit |

The lowest unit at which stored cargo items may be counted at. An inventory unit may be an individual item (example: blanket), storage container (example: bottle of pills) or kit. |

|

Handling Unit |

The lowest unit at which a stored cargo item is handled. In the context of a warehouse, the handling unit may be a carton that contains many inventory units. A handling unit may be a single unit, or an entire pallet. |

|

Material Handling Equipment (MHE) |

MHE is any form of mechanical equipment used to facilitate the loading and offloading of cargo, or the movement of cargo around an open space such as a port or a warehouse. MHE includes forklifts, cranes, pallet jacks, and more. |

|

Pick Order |

The order generated by a requestor and communicated to a warehouse indicating the quantity and type of SKUs to be pulled from inventory and shipped. |

|

First In / First Out (FIFO) |

An inventory and asset management system in which the oldest received inventory items on hand are the first removed from inventory. |

|

First Expired / First Out (FEFO) |

An inventory and asset management system that emphasizes and the movement of items based on their relative expiration dates. |

|

Non-Food Item (NFI) |

Any stored item that is not food in nature. In the humanitarian context, NFI items usually refer to durable, non-perishable items such as household and shelter materials. NFI management in humanitarian settings usually does not require advanced storage solutions, unlike storage of medicines or medical consumables which may require temperature controls. |

Warehousing Strategies

‘A warehouse is a planned space for the storage and handling of goods and material.’ (Fritz Institute)

The overall warehousing needs of a humanitarian organisation are generally specific to the needs of individual response activities and the overall objectives of the organisation itself. Organisations that deal with large volumes of non-perishable goods may need to have multiple warehouses in multiple locations, while organisations that focus on targeted special interventions – such as psychosocial programming – may have very limited need for a detailed warehousing strategy and may choose to procure and deliver directly from vendors as required by the project. Beyond just anticipated volumes of goods, special storage needs will also dictate a warehousing strategy; managing medical commodities requires far more detailed stock management and possibly specialised storage conditions, while durable non-food items (NFIs) may hardly need anything more than basic protection from the elements.

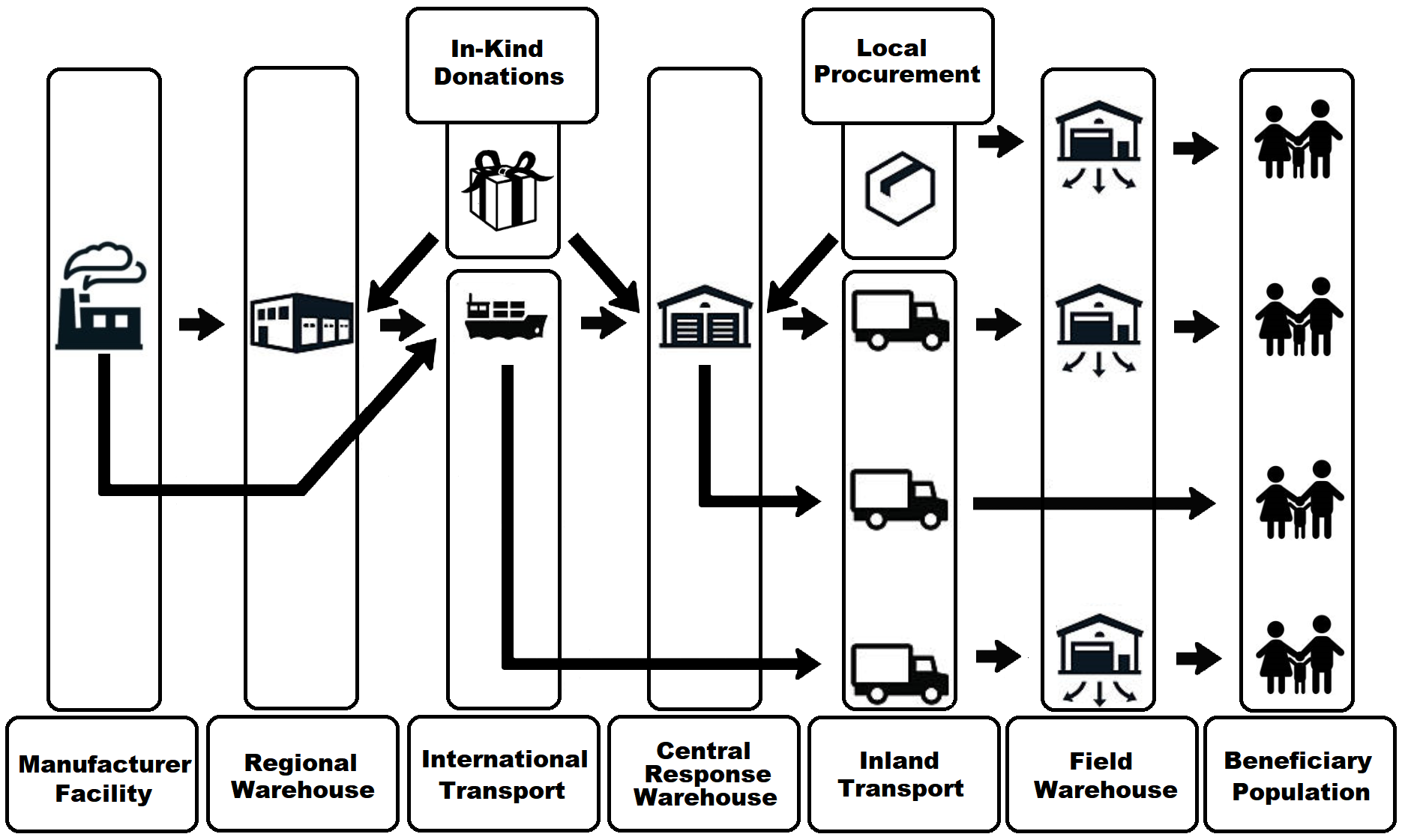

In general, humanitarian aid agency's follow a model for delivering goods to affected beneficiary populations similar to commercial distribution networks, comprised of international and local warehouse facilities that serve as consolidation points, feeder facilities and last mile distribution points.

Example: Overview of a general humanitarian supply chain and warehousing needs.

Regional/International Warehouses

Many international humanitarian response organisations have adopted a strategy of pre-positioning relief supplies in large warehouses not located in the countries of response operation, usually located in one or more strategic regional locations. The development of regional warehouses as lead to a general reduction in time required to respond to rapid-onset emergencies, as well as promotes a more reliable and consistent supply of physical relief items for countries of operation located around the region served by the warehouse.

An international or regional warehouse serves as consolidation point for items as they are received from vendors, donors or partners, enabling humanitarian response organisations to inspect, kit, segregate, repackage, or otherwise prepare cargo for further onward movement. In doing so, regional and international warehouses function as both pre-positioning facilities – holding cargo in case of a rapid unforeseen emergency – and as a feeder facilities – warehouses that slowly resupply warehouses further down the supply chain.

Though many agencies have adopted the regional facility strategy, regional warehouses should not be considered an automatic or default solution. Maintaining a large warehouse - especially one in a remote location not necessarily in the same country as an agencies headquarters – can be quite expensive, and requires additional staffing and time to ensure basic standards are met and the facility properly functions. If an agency is not prepared to commit to paying for multiple years of storage in a remote location, or cannot support the technical oversight or man-hours associated with the proper running of a facility, the agency may choose to completely outsource its regional warehouse management, or forego a regional response warehouse altogether.

Positioning a Regional Warehouse

When deciding on the location of a regional warehouse, the following points should be considered:

- Readily available access to a high volume of intermodal international transport – Is the warehouse near seaports and airports of sufficient size and throughput capacity?

- Relative location to the area of response – Does the region have sufficient response activities and does the location match the overall area of planned intervention?

- The nature of planned interventions – Will the warehouse serve rapid response activities? Or will the warehouse only feed into longer ongoing activities?

- Political climate of the country – Is the government of the country in which the regional warehouse located stable and not prone to conflict, ouster or drastically changing policies?

- Economic feasibility – Is operating in the country cost effective? Are there incentives such as free trade zones or humanitarian exemptions that reduce costs of international operations?

- Access the correct amenities – Does the location have facilities of the right size and quality required? Is there need for climate controlled or bonded storage?

- Access to sufficient technical support – Are there skilled labourers/companies readily available on the market who can manage and conduct special tasks like repairs?

Any of the above mentioned points can have adverse effects on the ability of a regional warehouse to perform its core functions.

Operations of a Regional / International Warehouse

Regional/international warehouses can be purpose built or purpose designed facilities operated by permanent staff that has been trained in all the areas necessary to run an efficient facility, or stock can be held utilising some version of a third-party logistics provider (3PL) staff and facilities. Ideally, any regional or international warehouse would use computer-based inventory management tools, with software to help in the planning and management of the warehouse. The operating environment of a primary regional or international warehouse used for pre-positioning should typically be relatively stable, and overall attention focused on the efficient and cost-effective warehouse operation. Numerous organisations have centralised pre-positioning facilities strategically located globally. Some of these offer extended services to other humanitarian organisations on a cost-plus operating charges basis, such as the United Nations Humanitarian Response Depot (UNHRD) Network.

Central Warehouse – Area of Response

The need and number of warehouses required in an area of response depends on volume and type of activities undertaken and locations of operation. Many response organisations prefer to keep at least one central warehouse in a country or area of response.

A central warehouse in the area of response is typically in either the capital city of the country of response, or in a major commercial hub within the country of response with sufficient infrastructure. The ultimate location of the central warehouse can be anywhere, insofar as it meets the needs of the organisation and the response objectives. In large areas of response, or in large activities, organisations may want a large warehouse in more than one location. The general position of a large central warehouse usually includes its relative proximity to sea and airports, manufacturing facilities, highly skilled or specialised labour or services, and readily available in-country transport services. Central warehouses can be directly managed by the agency, including staffing, rent and security, however in contexts with sufficient commercial activities, a central warehouse may be contracted out to a third-party provider.

The central warehouse serves as the primary reception point for goods flowing into a country, as well as a consolidation point for goods purchased locally. The size of a central warehouse depends on the anticipated volumes of goods themselves, the expected throughput of cargo, and the ancillary activities such as kitting that may occur on site. The overall purpose of a centralised warehouse strategy would be to provide sufficient and controlled flow of relief items to more remote or harder to access locations, keeping enough on hand to meet demand at all times. Some organisations may wish to forego a central warehouse strategy all together in lieu of arranging direct deliveries from vendors or international ports of entry to field warehouses or beneficiary distribution sites.

Field Warehouses

Field level warehouses are another strategy many response organisations have adopted. A field level warehouse is usually towards the end of the supply chain, near the last point of distribution to the beneficiary. Field warehouses can come in a variety of formats, ranging from tents and mobile soft sided structures to small hard sided structures. Some field warehouses might be just as large as a central facility depending on need; what defines a field facility is its proximity to programmatic activities and its role as the last stop en route to beneficiaries.

Field level warehouses usually do not have same level of built up infrastructure as central or international warehouses. Storage conditions at the field level are usually limited at best, and significant improvement might be required for special storage such as temperature-controlled requirements. Security in field level warehouses is also a primary concern, and additional infrastructure such as built up fences and additional guard services may be required. Cargo will likely be moved and stacked by hand with limited storage equipment such as shelving available.

The warehouse work force may be casual labour that has never worked in a warehouse before, while and the inventory system is more likely to be paper based. Often, the situation while setting up a field level warehouse initially chaotic, sometimes dangerous and coupled with a humanitarian need which may be very urgent. The management style must therefore be practical and action oriented with a focus on making the humanitarian goods available as quickly and efficiently as possible, while remaining accountable at the same time.

Storage Arrangements

When approaching warehousing, either at an international or response level, there are a variety of options available. Some options – such as government partnerships or temporary structures – make sense for short term or emergency contexts, while larger more sophisticated warehouse solutions might require long term investment and substantial resources over time. Below some of the solutions available to humanitarian agencies.

Self-Owned / Self-Managed Storage – Many humanitarian agencies with long term strategies and well-defined response plans choose to run their own warehouse facilities on a permanent basis. Self-managed solutions include owning an entire warehouse structure and the ground surrounding it, owning a warehouse structure but leasing the grounds upon which it’s built, or renting or leasing an entire warehouse/storage facility and the grounds surrounding it.

Self-managed warehouses can bring total control to an aid agency, but come with their own challenges:

- Needing to identify and manage physical space.

- Identifying, training and managing personnel.

- Assuming most or all cost and risk associated with running the facility.

- Establishing and adhering to warehousing and stock management policies.

Due to the nature of most humanitarian contexts, agencies tend to own or operate their own facilities in the affected countries. As such, humanitarian agencies focus on and develop strategies largely for country and field level warehouses, sometimes with an emphasis on the lowest operating parameters. Agencies may choose to self-own or self-manage larger regional or international warehouses too, however this comes with increased complexity and operational knowledge.

Commercial – Commercial rented or leased warehousing space can be a very attractive option for many agencies, either for rapid short-term solutions or for remotely managed facilities. Renting commercial space brings several advantages:

- Permanent storage structures already built.

- MHE and racking/storage equipment already installed.

- Advanced warehouse management software may already be in place.

- Warehouse workers already trained and readily available.

- Security precautions already taken.

- Flexibility.

Storage with a commercial third-party provider can vary based on contract type; humanitarian agencies may wish to rent an entire warehouse facility for themselves, or they may wish to only pay for the physical space inside a warehouse that they use. The nature of billing for commercial warehouses varies between contracts as well, but the following rates are common:

- In and out charges per pallet or cubic meter.

- Storage rate per day/week/month, charged per pallet position occupied or cubic meter.

- Packaging and labelling fees.

- Offloading/Loading charges per vehicle.

- Monthly/annual security and insurance charges.

Buying into a warehouse arrangement – especially one managed by a large international company is a good way of increasing covered storage space quickly, and is useful for storage sites in regional or international settings where permanent employees of the respective aid agencies are not based. Commercial warehouse solutions tend to only be useful in more developed contexts, or areas not prone to civil unrest. Commercial warehouse providers are also not humanitarians by nature, and may engage in activities that humanitarian organisations disagree with, such as support to military activities. Each of these factors will need to be considered by agencies entering a commercial option.

Government or State Facilities – Government or state-run facilities include any storage situation in which a state or acting agent on behalf of as state manages part or all of a storage facility. Storage in customs facilities at ports, harbours, airports, and cross border transit depots will be government managed or run, and humanitarian cargo passing through such storage facilities is quite common. Some humanitarian organisations may choose to partner with local and national governments in non-customs or security settings, utilising government storage and/or augmenting government capacity through equipment and training. When partnering with governments, agencies must balance the anticipated capacities of the government in question as well as the need for impartiality and neutrality. Such decisions are entirely up to the mandates and tolerance thresholds of the individual agencies who may choose to do so.

Partner/Common Storage Facilities – Some humanitarian agencies may wish to participate in communal or partner managed common storage options, such as those offered by Logistics Cluster partners in field settings or the United Nations Humanitarian Response Depot Network in key and strategic regional locations. Humanitarian agencies may also wish to enter into storage agreements between each other, however this typically requires individual agencies reaching contractual terms on risks and liabilities of each. Partner storage agreements might be extremely useful in the early days of an emergency, when warehouse space is limited or agencies may only have a limited presence of days or weeks at a time.

Types of Warehouse Space

Within the different storage arrangements available to partners, there are different functions that each of these facilities may provide. Some of these functions might include:

- Transit - for temporary storage of goods destined for different locations and need storage for a very short time.

- Pre-positioning – stock meant for unknown emergencies, usually sitting for long periods of times before being called forward. Stock in these facilities is usually designed with long term storage in mind.

- Bonded Storage – for storage of goods whose duty is unpaid and especially where the goods are destined to another country. Pre-positioned stock is often held in bonded storage to facilitate export. Customs holding facilities are usually bonded, but private companies can be certified bonded as well.

- Open Storage – storage contained in the open air, usually in a secure area. Not ideal for perishable products. In emergencies, sometimes open storage is the only alternative.

- Temporary Structures – usually capable of being established quickly in areas where regular permanent storage solutions aren’t available. Temporary structures might include tents or Mobile Storage Unites (MSUs).

Warehouse Management

Once a warehouse or storage location has been selected meeting the needs of the humanitarian organisation, and the overall response plan, and the facility has been fully restored or renovated to match the storage requirements, agencies will have the opportunity to design the physical layout of the warehouse space and any associated MHE or storage aids. It is important to understand the basics of a warehouse layout upfront to avoid problems later.

Physical Warehouse Layout

A proper warehouse layout should not impede the physical flow of work, increase the risk of damage to items, or impact physical safety of any persons in or around the warehouse.

Warehouses ideally follow the 70/30 rule – around 70% of the floor space of a warehouse will typically be used for storage of physical cargo, while around 30% will be open space for movement and work. The percentages are of used floor space are only guidelines, and space utilisation can be slightly more as needed. A warehouse should never be so full that cargo cannot be accessed, or persons cannot walk around safely inside. All cargo storage should be clearly visible and easy to navigate, and any person in a warehouse should be able to quickly identify locations of items and conduct piece counts with minimum effort.

Warehouses are usually arranged in easy to navigate grid like patterns, with “lanes,” “aisles,” and “rows” - open spaces between racks, rows and stacks of items that enable the free flow of people cargo and MHE. The width of aisles and rows depends on context; lanes in small storage facilities utilising ground stacking and no MHE should be .5 – 1 meter wide to enable access to human movement, while lanes in a large warehouse with racking may be up to 4-5 meters wide to enable access to forklifts or hand trucks. Lanes and aisles should be free from debris or cargo that could block the movement of people or handling equipment. There should be what is known as a “fire lane” – a free and open space between cargo and walls of a suggested 40 cm or the safest available space through which an adult human can move to enable quick exit. Exits in a warehouse should never blocked, and in large commercial facilities exits should be clearly marked.

Cargo must never be pushed up against walls or touching ceilings. In addition to making accessing cargo difficult, stored items touching the sides of structures runs a greater risk of mould or water damage, and cargo touching the ceiling can be an indication of cargo stored at unsafe heights. It is also advisable to keep a space at the loading/offloading areas of the warehouse to facilitate handling of cargo as it comes into/exits the facility. The size of the open space near loading areas depends on the size of the warehouse and anticipated activities – small facilities may only need a few square meters to manage sorting, while large facilities may need whole kitting arrangements.

For smaller remote warehouses or mobile storage units (MSUs) - Small field warehouses are likely going to be stocked and managed completely by hand. Proper layout can help ease the hand management process. Heavy or bulky items may be stored closer to exits of storage units to minimise efforts to manually move, while frequently used items should be moved closer to the front of the storage site to minimise distance required for porters to manually load/offload.

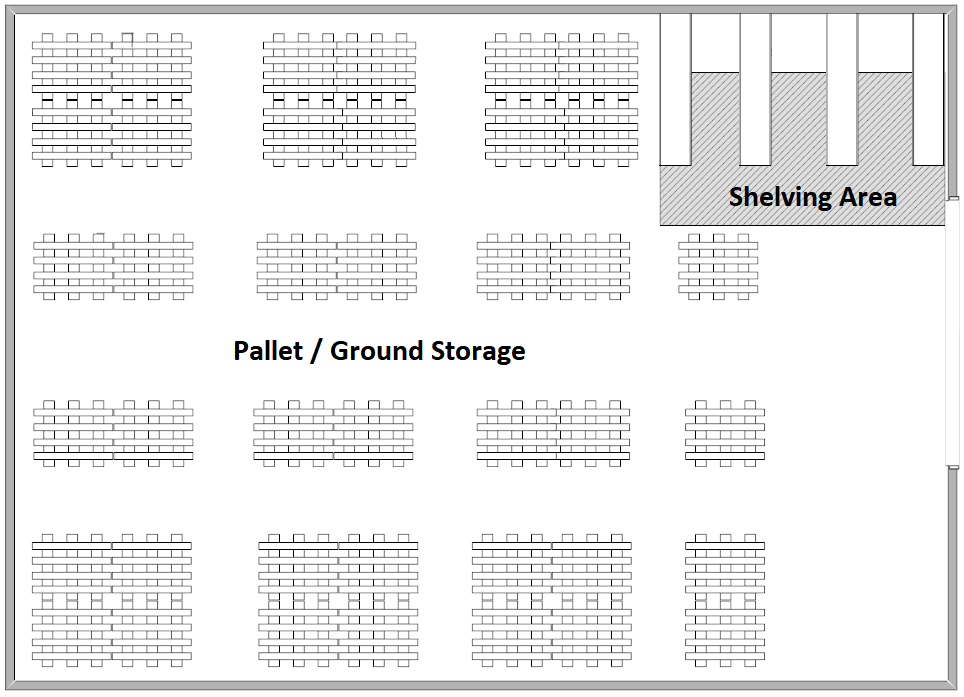

Example small field storage facility with ground stacking:

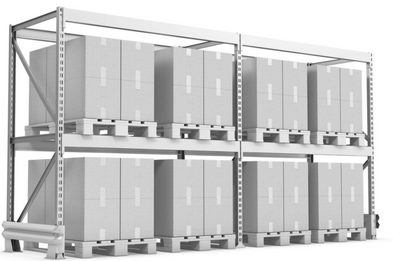

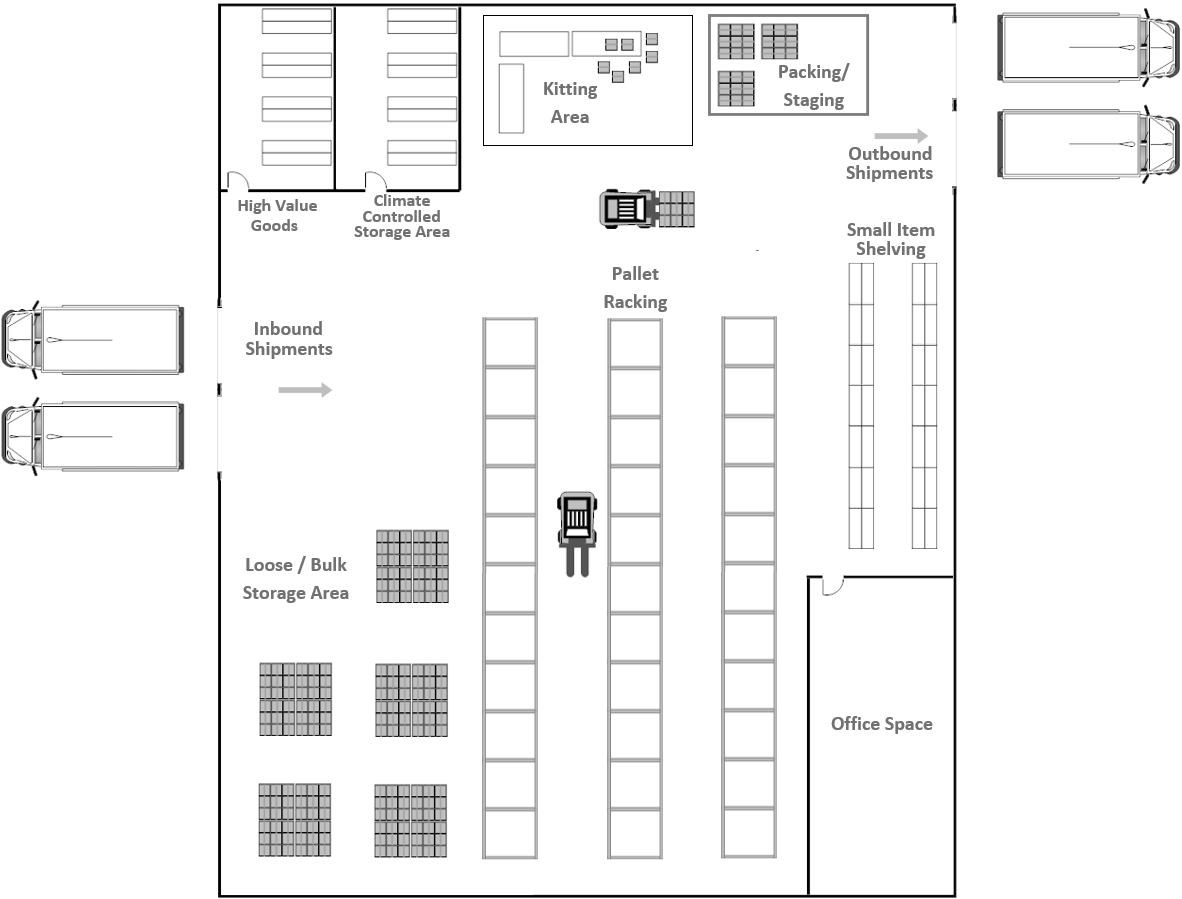

Larger Built-up Warehouses – Larger, more built up warehouses and storage facilities have a variety of layout and space management options. The overall need for the various components of a warehouse are dependent on the needs of the agency and the physical features of the available space. Some of the things aid agencies may wish to consider when looking at larger warehouses might include:

- Kitting areas identified and clearly demarcated. Kitting can occur inside the facility or outside the facility, depending on weather and available space.

- (Potentially) offloading and loading will occur in a different loading bays to facilitate the flow of cargo.

- Clearly defined staging areas for consolidation, loading and offloading.

- Climate controlled and other lockable facilities built or converted inside the warehouse, out of the way of the main warehouse flow.

- If any racking, shelving and bulk storage configurations are used at the same time, they are separated in clearly demarcated areas.

- If handling equipment such as forklifts are used, there are clearly defined areas where the forklift drives, ideally marked on the ground in visible paint or tape.

- Pre-defined parking and storage spaces for MHE. If MHE is using electricity, parking spots can also be charging locations.

- Use of drive up loading bays. Bays should be kept free from debris. Recessed bays prevented from flooding with proper drainage, and ramps must be adequate to fit and hold trucks.

- Roll up or swinging doors big enough to accommodate any handing equipment or cargo size.

Example warehouse floor plan of a larger warehouse operation:

Zonal Storage

Irrespective of the structure type or the size, space planners should consider planning the physical location of stored items relative to the amount of effort required to move or load them, including:

- Their size / weight

- Their frequency of usage

SKUs that have the highest volume of turn over - meaning the highest numbers of in and outs - should be stored closer to the cargo loading points of the warehouse or storage facility. The time and effort saved when moving these items between storage location and points of loading/unloading will have long term impacts on the overall timeliness of operations. Inversely, less frequently used items should be stored further away from the storage facility points of loading.

An exception to storing infrequently used cargo in the rear of a facility is planning on storing extremely heavy or difficult to move items near the front of a warehouse or storage facility, even if they are used only rarely. Items like machine parts or generators might be cumbersome or even dangerous to move around inside of a storage site, and keeping them closest to the exit is an advisable strategy. This is especially true for storage locations that are entirely managed by hand - planners should think of the physical capabilities and safety of loaders.

Site Selection Planning

There are many things to consider while selecting a location and/or a structure in which to establish a warehouse/storage facility. Rapid assessment templates for identifying storage space can also be found in the Assessments and Planning section of this guide.

Anticipated Cargo Needs

When planning a new warehouse space, organisations should consider what the anticipated cargo needs will be. Cargo needs will at least include the maximum anticipated volume at any given time, however they should also factor for special handling requirements or special activities, such as kitting. Understanding the full scope of the warehouse may require consultations between program and logistics personnel, and a mapping of programmatic activities over the coming period of time. Even a relatively small volume of cargo may require a large area in which to operate.

When anticipating the cargo and relief item storage needs, some of the following items should be considered:

- Total anticipated volume of cargo for the specific storage location.

- Numbers and types of independent types of goods (SKUs) needing to be accounted for.

- Interior space adequate for the anticipated flow of work.

- Need for handling equipment (MHE) for cargo items – MHE parking spaces, recharging, etc.

- Duration stored goods will stay for / the duration the storage site may be required for.

- Need for ancillary activities – repacking, labelling, kitting, break bulk, etc.

- Speed at which throughput/ancillary activities may be required – multiple loading bays, large dispatch area, etc.

- Need for special storage - cold chain, dangerous goods, etc.

- Additional planned buffer stock required.

More information on identifying and estimating cargo can be found in the section Finding Cargo Dimensions.

Irregular and Special Storage

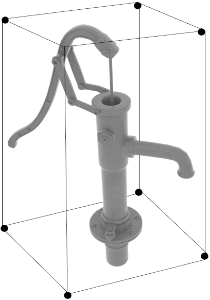

As agencies attempt to plan out space need in storage locations, they may encounter bulky or irregular items. In addition to planning generic outside dimensions, space planners should also estimate the fully required volume to adequately store an item, not just the outside dimensions.

| Irregular Shapes - Some irregular items, such as mechanical or farm equipment may have complex physical attributes that make space planning hard. When looking at highly irregular shapes, planners should consider the outside measurement of only the longest, widest and tallest parts of the item, as those are the parts that will come in contact with other stored items in a warehouse. To do this, planers should imagine an invisible box that is barely large enough to fit the irregular item, and use the “edges” of the “box” to calculate the total required space. In this way, the overall space requirement may actually be larger than they first appear. | |

| Nested Cargo – Some cargo items can be neatly “nested,” meaning that they can rest inside of or occupy space inside of each other. Buckets – a common humanitarian item – can fit inside one another, taking up considerably less space when stored appropriately. When planning space, organisations should account for nested storage by measuring the outer dimensions of the items while stacked/nested, and not the outer dimensions of the individual unit. In this way, overall space requirement may actually be less than they first appear. |

Physical Storage Space Aspects

Once the anticipated project and volume needs are established, organisations planning storage should review and assess the physical aspects and amenities associated with a potential storage space. Though there may be enough interior space to accommodate purely volumetric calculation, warehouses and storage sites may be lacking key infrastructure, or require substantial improvement to meet operational needs. A non-comprehensive list of physical space needs might include:

Physical Terrain:

- Ample space for trucks to enter, park, load/offload and turn around.

- Warehouse/storage site is not prone to flooding or other extreme weather events.

- Impact on the soil/sand/ground in the truck parking/offloading areas and kitting areas during routine activities – will the ground remain unaffected, or will improvement and maintenance be required.

Utilities/Amenities:

- Location/Building has access to basic unities - electricity, water, communications.

- Location has bathroom facilities on site.

- If required, the storage space has separated compartments for different storage areas/different storage needs – climate controlled, secured areas, etc.

- A usable office space of appropriate size.

- The capacity to refuel trucks – does the site have existing refuelling tanks, or do tanks need to be installed.

- An employee break/rest area.

- Prayer rooms (if required).

Structures:

- Proposed warehouse site has an existing physical structure.

- Existing structure and surrounding grounds are in good condition – if not, consider required upgrades.

- If required, location has drive-up loading bays for vehicles.

- Location has adequate walls, doors, and ceilings – if not consider cost and complexity of required repairs.

- If required, location has existing racking/shelving.

- Storage space floors smooth and free from cracks, and capable of supporting required activities.

- Walls are flat and free from pipes, exposed electrical wiring, support beams or other protrusions that might impact storage.

- Structure is free from any perforations that may lead to water or pests coming into the facility.

- There is proper drainage around structure – if not, consider cost and complexity of making drainage.

General Storage Location

The geographic location of the proposed site is also important – a poorly situated site may impact costs and time to adequately delivery humanitarian aid, and generally reduce opportunity to access markets and services. General things to consider when selecting a storage site are its proximity to key things, such as:

- Proposed site location is near the primary areas of intended use.

- If in a capital city, consider the need for the warehouse to be near the airport/seaport.

- If in a field setting, consider the need for the warehouse to near the intended distribution sites.

- Proposed storage site is near major arterial roads used for transport.

- Proposed location as easy access to transporters and casual labour.

- Storage facility will be easily accessed by organisation personnel.

Safety and Security

Overall safety concerns should be included in planned warehouse and storage space. Safety measures might include the physical components of a warehouse, but also the prevailing security surrounding the proposed location. When considering safety needs of a proposed site, organisations should also include security personnel in the planning process.

- Physical structure has a fire suppression system, and emergency exits – if not consider costs of installing fire suppression equipment.

- Storage location has built up walls/fences and access gates.

- Storage location has guard post and guard quarters, and possibly available guard service – many storage sites will require agencies to contract their own guards.

- Warehouse is not near any known or anticipated major targets - military bases, police stations, government offices, etc.

- Warehouse is not near potential hazards – chemical processing depots, fuel stations, landing strips, etc.

- Area is not known for security incidents in the past.

- Proposed location is not exposed and relatively inconspicuous, if possible.

Facilities Management

Once a facility has been fully selected and is operations begin, agencies will need to continue to maintain, or ensure that the third-party associated with running the facility maintains the physical structure, supporting equipment, and immediate grounds around the facility.

Site Grounds

The grounds around any storage facility should be kept open and free from objects as much as possible; debris, rubble, trash and weeds should be cleared out to avoid damage to vehicles and structures. Exposed wires or pipes should be properly buried or sealed; pipes or electrical equipment that cannot be buried should be well marked, painted red and/or have a secure or caged structure built around them. Drainage ditches should be clean and in working order at all times. Clogged or blocked drainage must be fixed to prevent flooding, and inadequate drainage must be dug if not already available.

Trucks must be able to enter, park, load/offload and depart the facility without difficulty, and ideally, more than one truck should be able to perform work at the same time. There should be adequate room for trucks to turn around in the allocated parking area; even if space is available, equipment or piles of scraps may hinder movement, possibly leading to delays or accidents. The grounds around truck parking and turning areas may need to be graded, paved or gravel/loam laid down to even the surface. An unimproved truck parking and turning space may lead to large grooves or divots in the ground, causing water to pool, mud to form, and vehicles becoming stuck or even damaging their undercarriages. Depending on weather patterns, truck turning and loading/offloading spaces may require continual maintenance seasonally or throughout the year.

Physical Structures

For storage locations of all sizes, there are a number of considerations to be had.

Electricity will be required to operate office equipment, lights and communications equipment. If electricity is not available on site, generators must be installed if possible. Any installed generator will need to be specified to appropriately meet the anticipated power load of the warehouse; and under powered generator will cause equipment failures and require constant maintenance, while an overpowered generator will end up costing more in fuel and maintenance. If a generator is used, agencies must develop a plan for supporting a generator, including having a supply of fuel and spare parts, and identifying how the generator will be maintained and serviced.

If no bathroom facility is available on site, either one will have to be constructed or access to a restroom nearby defined. If the site has no running water, either a water distribution system will need to be installed and water tankered in, or some other form of water will need to be provided for washing. Drinking water should be made available to warehouse workers, and if no tap or purified water is immediately available, bottled water may need to be provided.

There should be space for office work to occur. Any office space should ideally be separated from the main warehouse floor, and have locking doors and drawers. Office spaces should be provided with basic tools, such as a printer, stationary, desks and chairs, electrical sockets, filing cabinets and internet access wherever possible. Smaller facilities may lack the ability to keep office equipment on site, and as such basic supplies can kept in a locker, or carried with warehouse crews as needed.

Warehouses may require additional ventilation, based on the weather conditions outside and the types of commodities store inside. Many larger warehouses have soffit vents to enable hot air to escape as it rises towards the ceiling. Smaller storage spaces may not have the proper structures to support permanent ventilation, and may need doors open during working hours.

For Mobile Storage Units (MSUs):

MSUs must be properly installed and maintained. Installation of MSUs must be facilitated by someone with experience in the process. Beyond just knowing how to assemble an MSU, MSUs must:

- Be built with either the front or back facing prevailing winds to minimise wind pressure.

- Should not be constructed in a low point, or in a location prone to flooding.

- (Ideally) MSUs Should be built on free standing slabs to elevate the MSU above waters caused by rains or flooding.

- MSUs must be properly secured, lockable from the outside and difficult for anyone to climb under the outer apron.

Damage to physical MSUs such as warping of beams or tearing of vinyl siding must be assessed, and repairs conducted by a knowledgeable person. Cracks or damage to MSU foundations must be repaired quickly to prevent further compromising the structure.

For Built-up Hard Sided Structures:

Damage to physical structure should be addressed and repaired. Cracks or holes in ceilings and walls should be addressed as soon as they are identified. Storage facilities should have solid, locking doors and windows. Windows that are low enough to be easily reached and accessed by an adult human should be covered with bars or grating of some kind.

Storage structures should have adequate inside lighting:

- If ambient lighting isn’t sufficient for daytime usage, agencies should consider installing additional lights for daytime use.

- Light should be sufficient for operating at night time. Larger facilities may need extensive lighting installations.

Vector Management

Vectors are defined as rodents, insects, or anything that may spoil or damage stock on hand. Proactive vector control is important; rats and insects don’t just impact food – they can also damage anything woven from organic material such as blankets or clothing, and can completely destroy stocks of medical grade consumables. An untreated infestation of can lead to large problems down the road, any identified infestation or pest must be dealt with immediately. Warehouses will need enact some form vector control depending on the nature of the stock, including:

- Fumigation – external companies may be able to be contracted to provide fumigation services.

- Rat traps/glue – placing pre-made traps around the warehouse to capture rodents.

- Keeping warehouse floor clean at all times.

- Removing spoiled/rotten items from the general stock and disposing as soon as possible.

In the event an infestation is identified, records should be taken of the date and type of treatment used. Records can help schedule routine fumigation or product inspection, but also may indicate seasonal problems as well.

Fumigation

The overall need for pest and infestation control depends on the duration, storage conditions and type of commodities stored. Food in particular is sensitive to attracting pests, and agencies specializing in food may have special fumigation schedules. A general best practice is to enact fumigation once every six months, however ideally stock should rotate quickly enough to avoid the need for fumigation. In other instances, fumigation may be required every 3-4 months, or as soon as an infestation is discovered. As a general rule most insect pests under humid tropical conditions can be expected to multiply about 50 every six weeks, meaning an untreated infestation can become a large problem very quickly.

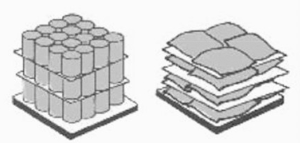

Fumigation can be for an entire warehouse or storage site, or for just one portion of stock, however it is strongly advised to fumigate all perishable SKUs at the same time. Fumigation in storage contexts is usually done using what are called "fumigation sheets" or "gas tight sheets" - large impermeable tarps that cover stored items. When using these fumigation sheets, chemicals specifically used for fumigation are pumped under the edge of the tarp, while the edges of the tarps are weighed down to prevent air movement. Use of these tarps concentrates fumigation efforts into specific areas and maximizes impact.

When undergoing fumigation, workers and managers should always consider the following:

- Fumigation should only be carried out by a trained professional, or a specially licensed company. Agencies requiring fumigation services should enquire with their procurement team about what may be available on the market. At no point should an agency attempt to fumigate themselves without special training!

- Even if fumigation is done under tarps, workers should vacate the storage space until they can safely return, as indicated by a trained professional.

- Proper safety equipment should be used by all persons working with or around fumigation.

- Fumigated items will need to be properly aired out before handling or distribution.

After fumigation, continual inspection may be required. If infestations persist, there may be a need to alter storage or delivery methods. The use of additional liquid based pesticides may be required to spray around the exterior or floor of storage spaces.

Physical Warehouse Maintenance Schedule

Below is a suggested periodic maintenance schedule for warehouse management.

|

Clean |

Check |

|

|---|---|---|

|

Daily |

|

|

|

Weekly |

|

|

|

Monthly |

|

|

Warehouse Equipment Maintenance Schedule

All equipment in warehouse facilities - including racking and shelving - will require periodic maintenance. This may include replacing parts, applying lubricants, checking batteries, conducting daily charging or cleaning, or just conducting ongoing inspection to ensure that service equipment and physical holding structures are not displaying signs of damage and distress. Generally, the service schedule for different equipment items will be provided by the manufacturer, however the overall need to conduct daily or weekly inspections may also depend on the size of the warehouse and the overall daily handling requirements. The larger the facility, the more pieces of equipment will likely require maintenance. Additionally, warehouses with high degrees of throughput may also require more regular maintenance. Warehouse managers should develop a maintenance schedule for warehouse equipment breaking down daily, weekly and monthly/yearly service needs, and should also maintain separate logbooks for key pieces of equipment, such as forklifts. Proper tracking of maintenance will increase the lifespan of expensive items, and will increase overall safety of the warehouse environment.

Handling Equipment and Storage Structures

The ways in which cargo is physically stored in a warehouse can dramatically increase usable storage space, increase efficiency, and impact safety. Generally, there a few main categories through which cargo is physically stored and handled.

Shelving

Unlike racks which are used to manage pallet sized loads, shelving used in warehousing is useful for:

- Small, low quantity, loose items – example: vehicle replacement parts.

- Items that are dispensed at small quantities – example: medications.

- High value items – example: computer equipment.

Shelving can easily be constructed in remote field warehouses from local materials, insofar as the local materials can physically support the required stored items. Shelving can also be installed anywhere inside a larger warehouse, however the location should make contextual sense. As an example, shelving may be used as an intermediary stage of order fulfilment; a warehouse may have pallets/large cartons of items small items, but only receive pick orders for low quantities. A reasonable quantity of stock may be moved to pre-defined shelf space to facilitate ease of fulfilling low or item level pick orders. Shelving may require a separated space physically separated from the main warehouse floor; high value items or controlled goods might be better suited stored on shelving in a separate lockable space.

Shelving installations should be ergonomic; shelves should not be so deep that an average height adult cannot reach to the back of the shelf, while shelves should not reach unsafe heights, and if possible, should avoid requiring ladders or stools to reach the top.

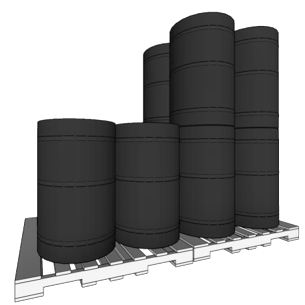

Loose Stacking / Ground Storage

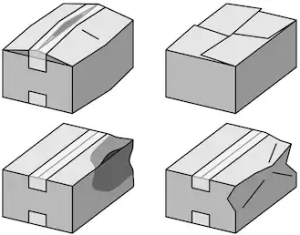

Ground storage includes anything that is stored on the floor of a warehouse, often compiled in stacks. Items stored on the ground should never be directly in contact with the warehouse floor; cargo should rest on pallets, or if pallets unavailable, tarpaulin. The general configuration of ground floor stacks will vary based on the storage needs, including:

- The number of different items SKU items that might require accounting.

- The weight of cargo limiting height.

- The physical nature of the cargo; cartons can be evenly stacked, while irregular kits in sacks might be piled like a pyramid.

Ground storage of loose items is quite common in humanitarian settings. Most remote field warehouses are usually too small to accommodate special equipment installation, lack the sufficient infrastructure to properly support MHE, or are temporary structures in nature. A substantial portion of humanitarian relief supplies don’t necessarily require advanced handling either. There are several tricks to properly managing stacks of cargo, which are covered in the stock management section of this guide. Humanitarian agencies should resist the urge to use ground handling in all contexts despite its prevalent nature; commodities such as medication may benefit from not being stacked in a pile. Space planers should also resist the urge to fill up all available space when utilising ground storage; warehouses and storage facilities using ground storage and stacking should still observe the 70/30 rule, keeping lanes and aisles open for safety while making room for loading and offloading.

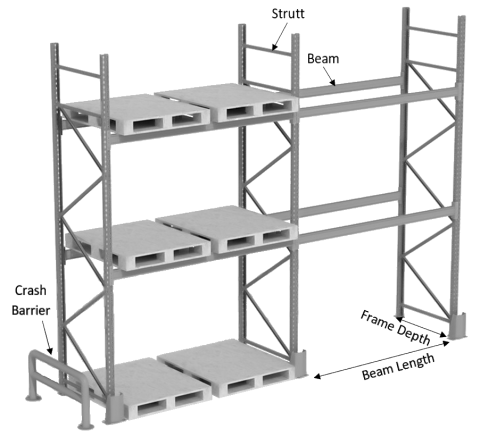

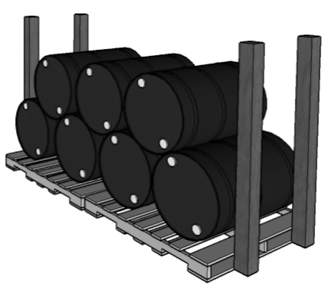

Racking

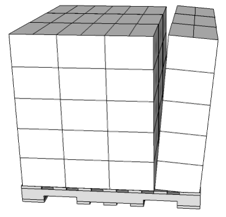

Warehouse racking – sometimes referred to as pallet racking – is a heavy-duty metal superstructure that is specifically designed to hold large, pallet sized items. Each space where a pallet might fit is referred to as a pallet bay, and pallet bays are generally counted as “pallet positions” when counting warehouse space availability. Palletised cargo, bulky items stored on pallets, or oversized cargo of a specific size can be loaded onto pallet racking using a forklift. The bottom bay can usually be loaded with a pallet jack, or may kept open for hand stacking smaller items. Properly utilised racks can dramatically increase the storage capacity of a warehouse, maximising three-dimensional space to the best of its ability.

Pallet racks can be built to meet the floor plan and storage needs of a warehouse, and the cross beams upon which pallets sit are adjustable to match changing storage height needs. There are different types of racking system that can be considered in accordance with the storage requirements- Very Narrow Aisle (VNA), Selective racking, Drive-in/Drive through, Candiliver, bins, and more - however any agency considering different options should consult with private companies offering installation and management services to better understand the requirements and needs of each. The vertical space between rack cross beams should be reasonable; too high and space is wasted, too low and pallets may become stuck or cannot be properly inserted. An average height is around 1.5 meters, but adjustments may be required based on context of the pallet or items stored. Racks can be built to hold vertical stacks of pallets up to 20 meters tall, however racks should never exceed the safest lifting height of the available forklift on site, nor should they get closer than 2 meters from the ceiling. The horizontal frame depth between rack cross beams should not be wider than the expected pallet type to prevent pallets falling through, and irregular shaped objects may not rest neatly or safely without an additional flat surface resting across the two beams.

Pallet racking systems should only be installed by professional companies with demonstrated experience. Racking systems also require warehouse floors to be sufficiently thick and strong, as racks will need to be physical bolted to the ground. Racking must be safely operated around and maintained; physical racking structures must not show signs of distress, corrosion or damage. Compromised racking structures can easily collapse causing substantial loss to stored items and serious injury or death. Wherever possible, racks should have some form of physical crash barrier at corners of rows and lanes to prevent damage from handling equipment. Only persons trained and certified to operate a forklift should be engaged in loading and offloading cargo from metal racking structures.

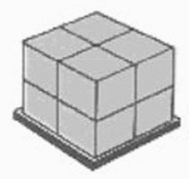

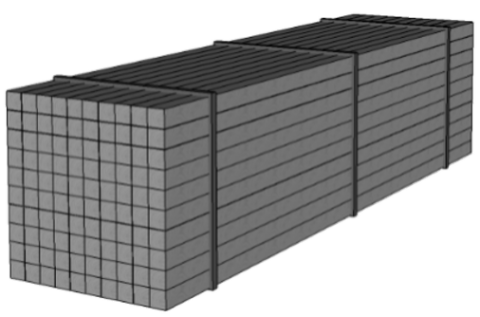

Stacking Frames

Related to pallet racks, stacking frames are pre-made metal super structures that are designed to vertically stack cargo. Unlike pallet racks, stacking frames are free-standing, and are highly customisable and modular.

A single stacking frame is typically cubic in shape, and around 1.5 x 1.5 meters at the base, though sizes vary. Most stacking frames can either be nested into each other when not being used, or even be taken apart, saving space. Stacking frames are useful for:

- Stacking irregularly shaped cargo.

- Warehouse space with constantly changing racking needs.

- Quickly moving entire racks from one place to another.

If loose cargo is stored in the racks, it should be properly braced, secured, or wrapped. The entire frame can be moved by a forklift, and frames can be easily stacked as high as safely possible to take advantage of vertical space. Unfortunately, stacking frames can only be used in warehouses with smooth and stable floors, and where forklifts can safely operate. Many larger facilities use stacking frames to augment racking and shelving, especially for irregular shaped items that cannot be easily stacked otherwise.

Pallets

Pallets have become ubiquitous across transport and warehousing operations globally, however there is a wide variety of sizes, dimensions and physical construction of pallets. Though local warehouse managers may have very little control over the types of pallets that might arrive, an understanding of pallet differences can assist with both space planning, and safe utilisation of racking and MHE.

Pallets generally come in a few standard dimensions. ISO Pallet Standard Dimensions are:

|

Dimensions (Metric) |

Dimensions (Imperial) |

Floor Space (Square Meters) |

Region Most Used In |

||

|---|---|---|---|---|---|

|

W (mm) |

L (mm) |

W (in) |

L (in) |

||

|

1016 |

1219 |

40 |

48 |

1.2 |

North America |

|

1000 |

1200 |

39.37 |

47.24 |

1.2 |

Europe, Asia |

|

1165 |

1165 |

45.9 |

45.9 |

1.4 |

Australia |

|

1067 |

1067 |

42 |

42 |

1.1 |

North America, Europe, Asia |

|

1100 |

1100 |

43.3 |

43.3 |

1.2 |

Asia |

|

800 |

1200 |

31.5 |

47.24 |

1 |

Europe |

Both the square meters and side dimensions of pallets have implications for how pallets consume floor space in warehouse and trucks, how pallets may fit through doors, and how a pallet might be stored in elevated pallet racking. In addition to differing dimensions, there are different body constructions and different materials used in building pallets. Common pallet constructions:

|

Two-way entry pallet - close boarded, no base board |

Four-way entry pallet - perimeter base |

|---|---|

|

Four-way entry pallet - close boarded, 3 base |

Two-way entry pallet - reversible |

|

Four-way entry pallet - close boarded, perimeter base |

Four-way entry pallet - open boarded, 3 base |

|

Four-way entry pallet - wing type |

Two-way entry pallet - wing type |

- Pallets come in either two-way entry or four-way entry, meaning forks can lift from only two side or all four sides.

- Pallets can be reversible or non-reversible. Non reversible pallets mean only one side has a stable surface upon which cargo can be stored. Non reversible pallets are sometimes called “skids.”

There may also be requirements for pallets to be fumigated, heat treated, or made of plastic. Pallets are predominantly made of wood, and different wood sources are more prone to infestations that can impact stored goods. Some countries even have regulations prohibiting the use and transportation of untreated wood pallets.

A printable guide to pallet dimensions can be downloaded here.

Material-Handling Equipment (MHE)

Material-Handling Equipment (MHE) is defined as any mechanised or manual machinery to assist with the movement of cargo, either around a warehouse or during the transport process.

Proper use of MHE requires not just the equipment, but the infrastructure to surround it. Pallet jacks, carts and some forklifts will only work on flat, hard and smooth surfaces. Some MHE – forklifts in particular – require external power such as diesel, natural gas or electricity. Without the ability to supply this external power to MHE that requires it, the MHE is essentially useless.

MHE is designed to do heavy lifting; it can help warehouse personnel move heavy loads but can also be very dangerous. Forklifts can easily hurt or kill workers, while a pallet jack may enable workers to move pallets far heavier than they realise, compromising the safety of others. While utilising MHE, warehouse staff should be properly trained and use proper safety equipment.

MHE typically involved in warehousing operations might include:

|

Forklifts – A mechanised power loader capable of lifting full pallets and heavy equipment. Forklifts come in a variety of sizes to meet a variety of load needs, but generally come with an enclosed cab and a four wheel base. All forklifts will have a hydraulic or chain powered “mast” capable of extending and lifting cargo vertically. The height and lift capacity of the mast depends on the rating of the forklift, and more information can be found from the manual or manufacture website. Depending on the make, forklifts can be powered by either battery, compressed gas, or diesel/gasoline. Forklifts are generally designed for either use inside a warehouse with even surfaces, or for all terrain outdoor use. Before obtaining a forklift, humanitarian agencies should consider:

|

|

|

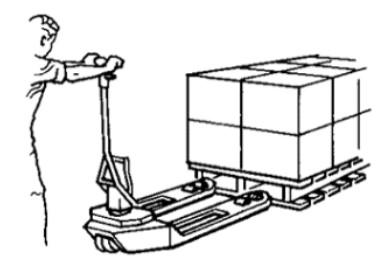

Pallet Jacks – Sturdy, low centre push cart with forks capable of lifting a pallet a few centimetres off the ground. Pallet jacks are typically only powered by hand, using a hydraulic piston to gently lift and lower pallets. Pallet jacks generally require flat surfaces and only work indoors, but can assist with moving large loads quickly and with minimal effort. |

|

|

Rolling Warehouse Ladder - Heavy duty, reinforced metal ladder that can be repositioned around a warehouse to enable workers to reach higher shelves/racks. These types of rolling ladders tend to have extremely sturdy and wide steps that enable workers safely and easily carry cartons and other handling units up and down. These types of rolling ladders typically only work on solid, smooth surfaces. |

|

|

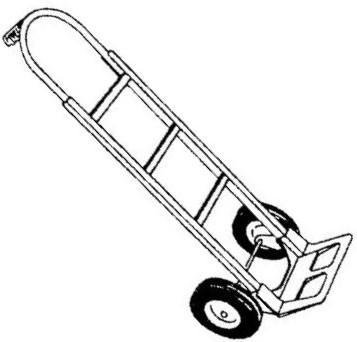

Dollies – Occasionally referred to as hand trucks, dollies allow for moving of stacked cargo without the aid of a pallet. Dollies can be useful for moving relatively small loads, such as a stack of cartons, or a single large item, such as a large roll. Many dollies are designed with heavy duty inflatable ties to assist with operating outdoors. |

|

|

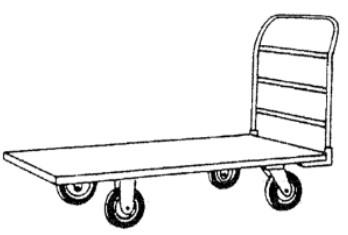

Push Carts and Others – There are a variety of other simple tools to facilitate the movement of cargo around a warehouse or between mode of transits. A very common tool is a standard push cart, however there are many variations on sizes and components, and users should select the support tools most useful to them. |

Basic Support Items – Part of a properly functioning warehouse is the ability perform simple maintenance, conduct routine product inspection and address small issues without having to source external support. Basic tools and support items that should be available in any warehouse include:

- Weighing scales.

- Measuring equipment – tape measure or yard stick.

- Sturdy ladders and step stools.

- Rope, twine, plastic binding, and sturdy wire.

- Packaging tape and duct tape.

- (if required) Plastic pallet wrap.

- Cleaning supplies – broom, bucket, mop.

- Face masks and gloves.

- Ear and eye protection.

- High-visibility vests.

- Heavy-duty pens.

- Note pads and writing materials.

- Safety knife and scissors.

- (if required) Industrial fans.

- Chairs and folding table.

A warehouse working with large MHE and palletised cargo will have some different needs than a small field level warehouse. Additionally, larger facilities may have contracts with professional cleaning or repair companies, while smaller facilities will be purely self-managed. The basic tools and equipment of a warehouse should reflect the daily needs of the operation, and the prevailing environmental conditions. Planners should think through their basic supply needs when establishing a warehouse; an overabundance of basic tools may cost more, but a lack of tools can stop an operation entirely.

The Cargo Handling "Human Element"

In the context of humanitarian field operations, cargo is either heavily or exclusively moved and loaded by hand. Humans are far more versatile than typical MHE, including being able to achieve specialty tasks, however there are also limitations to human labour. Logistics personnel tend to calculate needs of warehouse handling based on the maximum performance of hand loaders and ignore the fact they have limitations like anyone else. When working with or scheduling hand loaded cargo operations, a good practice is to remember:

- Hand loaders require “recharging” periods such as water breaks or meals.

- Resource planners may need to factor prayer times into warehouse activities.

- People get bored with repetition which may increase mistakes.

- The overall efficiency and speed of hand driven operations will go down over the period of a day.

Injury and strain are common in warehouse operations, and human managed operations must acknowledge risks and needs of any tasks.

Warehouse Safety and Security

When establishing any warehouse or storage facility, adequate physical security measures must be enacted. In humanitarian contexts, relief supplies are incredibly attractive to thieves – often humanitarian supplies are in short supply and the chaotic environments and limited infrastructure make theft frequent and hard to trace. Additionally, the overall operating environment may make responding to injuries caused in the workplace difficult. Aid agencies should have solid measures in place ensure a safe and secure workplace for stored items and workers.

Perimeter Security - Storage facilities should have in-tact perimeter walls or fences. The premiers should not have any gaps or holes, and be high enough and sturdy enough to sufficiently prevent casual thefts or easy access. The perimeter areas should be as shaped as regular as possible to avoid potential blind spots where unauthorised access may occur. If possible, sufficient perimeter lights should be installed, and should function throughout the entire night.

Guard Service - The warehouse ideally should have some form of guard service, either privately managed or sub-contracted through a third-party company. Guard services should have sufficient numbers to cover all hours of the day and night with regular 8-10 hour shifts. Having one or a few live-in guards may mean guards reach fatigue and/or won’t be alert at all times, especially throughout the night. Any guard service should also control the flow of visitors and vehicles through use of sign in/out sheets, and possibly even the need to ask for permission before letting outsiders in. Guards should also perform routine perimeter checks, looking to see if doors have been compromised, and responding to any suspicious noise or activities.

Fire Suppression – Warehouse and storage facilities of all sizes should have a fire suppression plan in place. Larger facilities may have professionally installed smoke detector and sprinkler systems in place. Sprinkler systems should be regularly inspected by a licensed company, and in compliance with national laws where required. Smaller or remote warehouses may not have the infrastructure or the available utilities to support an advanced fire suppression system, and should be outfitted with basic fire-fighting tools.

Irrespective of the warehouse space, fire extinguishers should be readily available. Fire extinguishers should be clearly visible to the eye, easily accessible, and be placed at least every 25 meters or closer if required by local regulations. Extinguishers should be inspected every 30 days to ensure the pressure valve reads as in the workable range, and that the canister does not display symptoms of rust or corrosion, and that the hoses are not split or damaged. At least once a year, extinguishers should be pressure tested. If at any time extinguishers do not pass inspection, they should be recharged or replaced as necessary. Consult the owner manuals or supplier for proper gauge readings.

At bare minimum, class A extinguishers should be placed throughout the storage space at the correct intervals, and class B extinguishers should be stored near any place reactive substances or flammable liquid such as fuel are stored. Many field location will also use what are known as “sand buckets” – buckets pre-filled with sand and stationed throughout the facility to also enable rapid suppression of a fire. Both are recommended for remote locations where water may be scarce and proper maintenance of extinguishers may be difficult.

Fire Extinguisher Classes Per Region:

|

American |

European |

UK |

Australian/Asian |

Fuel/Heat Source |

|---|---|---|---|---|

|

Class A |

Class A |

Class A |

Class A |

Ordinary combustibles |

|

Class B |

Class B |

Class B |

Class B |

Flammable liquids |

|

Class C |

Class C |

Class C |

Flammable gases |

|

|

Class C |

Unclassified |

Unclassified |

Class E |

Electrical equipment |

|

Class D |

Class D |

Class D |

Class D |

Combustible metals |

|

Class K |

Class F |

Class F |

Class F |

Kitchen Grade (Cooking oil or fat) |

Occupational Safety – Warehouse workers should be instructed and encouraged to engage occupational safety in any situation where storage is required. Occupational safety includes:

- High visibility vests worn by warehouse workers and visitors as needed.

- Warehouse workers have sufficient and adequate breaks.

- MHE is properly maintained, and support equipment such as ladders is not compromised or damaged.

- Staff who operate MHE are trained and/or certified for that equipment where required.

- Stocked first aid kits available on site.

- Warehouse workers wear proper protective equipment equivalent to the required working conditions, including gloves, hard hats/helmets, close toed safety shoes, ear and eye protection as required.

- Fire exits are clearly marked.

- Lanes for movement of MHE are clearly marked on the floor.

Situational Safety – As the storage site is established, agency security personnel conduct periodic reviews and follow incidents accordingly. Safety and security assessments of the warehouse and the surrounding areas should be conducted at least once a year, and security incidents occurring on site or in the immediate area should be properly reported in a timely manner.

Physical Storage Guidelines

Irrespective of the size of the warehouse/storage facility or nature of the storage arrangements, there are basic rules humanitarian organisations can use to enhance their physical stock management processes.

In any situation where cargo is stored for any period of time, it is strongly advised that humanitarian warehouse managers utilise both some form of inventory Ledger and a paper stock/stack/bin card system.

An ideal inventory Ledger will be electronically maintained, utilising some form of spreadsheet or special use software. The ledger should be constantly kept up to date, and should be easy to access and understand by any team member responsible for accounting for cargo on site.

Stock/stack/bin cards should be clearly visible from the floor of the warehouse, legible, easy to read, and utilise the local language of operation. Stock/stack/bin cards should match the inventory Ledger.

Stock managers must by default practice FIFO – First In / First Out – unless otherwise required to. Some storage facilities may have large volumes entering and leaving the physical facility, and managers must take care to ensure that old stock is not forgotten or ignored.

Perishable items with expiration dates must be closely tracked and dispatched in accordance with the practice of FEFO - First Expired / First Out. Items with expiration dates less than three months in the future or expired items should flagged and communicated to program staff to ensure they are properly utilised.

Stored cargo must always be separated from the ground, using pallets, tarpaulin, shelving, or racking. Warehouse managers should be constantly motoring the status and condition of stock on hand. All handling units should appear in good condition, and be free from avoidable damage of any kind, including water damage, punctures or rusting. If cartons or items appear to be crushed, punctured or experiencing damage from regular wear and tear, they must be separated, repaired (if possible), and returned to inventory in a manner that prevents future damage.

Stock Counts

There are a variety of methods for conducting physical inventories. Agencies should review different inventory methods, and set up guidelines and time intervals for conducting inventories, including ad-hoc and regularly scheduled annual inventories.

Damaged Items

Throughout the course of managing physical stock, damaged items will be discovered, either as a result of age, expiration, mishandling, or even from items that were defective in the first place. As damage items are discovered, they must be clearly marked and addressed. Some damaged items can be repaired, especially if damage is only to outer packing. An item that is ultimately still usable, but has damaged outer packing can be repacked into new cartons/bags where available, the packaging itself can be taped or sealed. Even if there are no replacement cartons/bags available, the usable items can be stored loose on the racks/shelf/stack and be marked for usage first during the next pick order.

If the core item is ultimately not usable due to extensive damage, spoilage or expiration, the item will need to be separated from the rest stored goods. Damaged goods should be clearly marked, and stored in a separated area. Depending on the severity of the damage, a loss report may need to be generated, including the number of units damaged and the associated values. As damaged items are removed from the general inventory, inventory Ledgers should be fully updated, with damaged items clearly indicated as being deducted from the full inventory count.

Damaged items may need to be returned to a vendor, handed over to third party authorities, or be disposed of.

Expiration Management

Under normal circumstances, warehouses are advised not to accept goods that have less than 6 months expiry period left, and should seek to rotate out items approaching 6 months left before expiring. Warehouse/stock managers should routinely generate regular reports that identifies those items that are due to expire within a user specified period, identifying each SKU, lot, quantity and date of expiry.

|

General Expiry Management Rules |

|

|---|---|

|

Ordering Items |

Incoming orders that contain expiration dates should be flagged and notified to the warehouse teams, and shared with relevant persons or departments that own the stock. |

|

At Reception |

All incoming stock items should be inspected for expiration dates at the point of reception. |

|

Ongoing Physical Checks |

Checking expiration dates should be part of the physical inventory process, including looking for new expiration dates not already identified in the stock/inventory tracking system. |

|

Items with 1-3 Months Expiry |

Persons or departments storing Items with expiration dates should be notified when they reach 1-3 months left until expiration on a weekly or monthly basis, through email or other formal communication. |

|

Items with 0-1 Month Expiry |

For items with less than one month until expiration, it is advisable to notify the person or department that owns the stock - either in person or telephone - reminding them of the situation and suggesting that the goods are removed as soon as possible. Multiple reminders may be required. |

|

Expired Goods |

Any items that have expired must be segregated from the rest of the stock, and all orders put on hold so that no expired items are accidentally delivered. The person or department that owns the stock must be notified by phone, email or in person, and all proper disposition steps must be followed in accordance with local regulations and organizational policy. |

Disposition

As warehouses continue throughout their operations, they will inevitably need to dispose of damaged, expired, recalled, or no longer required goods. Disposition of any item must be done in an ethical, environmentally friendly and legal manner, all in compliance with the internal policies of the organisation managing the facility. Options for disposition:

|

General Disposition Management Rules |

|

|---|---|

|

Donation/Resale |

Items still in usable condition can be sold or donated to other agencies or local populations in accordance with donor regulations and internal financial policies. |

|

Dispose |

Some items can be thrown directly into the trash without concern, such as small quantities of expired food stuffs or cardboard. |

|

Destroy |

Some items, such as expired medication, harmful chemicals, bulk foodstuffs, and special “dual use” or military grade hardware, may need to be actively destroyed. Many local authorities have regulations on the destruction of these items, and there may even be authorised companies certified in destroying key materials. Agencies should investigate local laws and seek out disposal companies whenever required. |

|

Re-export |

Items, such as heavy machinery, may need to be re-exported from the country of operation. Re-exporting of key items may be required by donors and national authorities, or may be just more cost effective than local disposition. |

Warehousing Documentation

The documentation requirements for warehousing can be vast, depending on the type of warehouse, regulatory controls over the stock or the facility, the types of commodities stored, or the specific activities of the agency running the facility. Documentation might include inspection reports, fumigation schedules, repairs, import/export documents related to bonded storage and more.

As an overview, most humanitarian agencies will use at least several standard documents across all of their storage operations, including large professional facilities all the way down to field level storage. These documents are essential for the proper audit and tracing of cargo as it flows in and out of agency managed facilities. It is important that this standard document be accurate, and that copies are properly kept – both at the site of operation, and eventually scanned/backed up in another location for wider historical record keeping.

Waybill/Delivery Note – Warehouses will often use common waybills as part of the overall documentation process. Waybills – also sometimes called “delivery notes” - come in many formats, and can represent either domestic or international deliveries. Waybills also tend to be generated by external third-parties, and are used for their own third-party tracking needs. If properly handled, at least one copy of the incoming waybill should stay with the receiving party (warehouse). If a copy cannot be left with the warehouse, the receiving warehouse should attempt to electronically scan a copy of the waybill, including all signatures and notes on it as evidence of delivery.

As cargo leaves the warehouse, waybills will also be generated. Agencies may wish to generate their own agency specific waybills to accompany cargo they pack and load. In other situations, third-party vehicles may generate their own waybills on the spot. In either case, warehouse workers loading cargo onto vehicles must ensure that the information contained on the waybill is accurate. Situations in which organisations may choose to use self-generated waybills may include:

- The vehicle is managed/owned by the agency.

- The destination of the vehicle is a facility or distribution site managed by the agency.

- The contract with the third-party trucking company stipulates that they must use agency specific waybills.

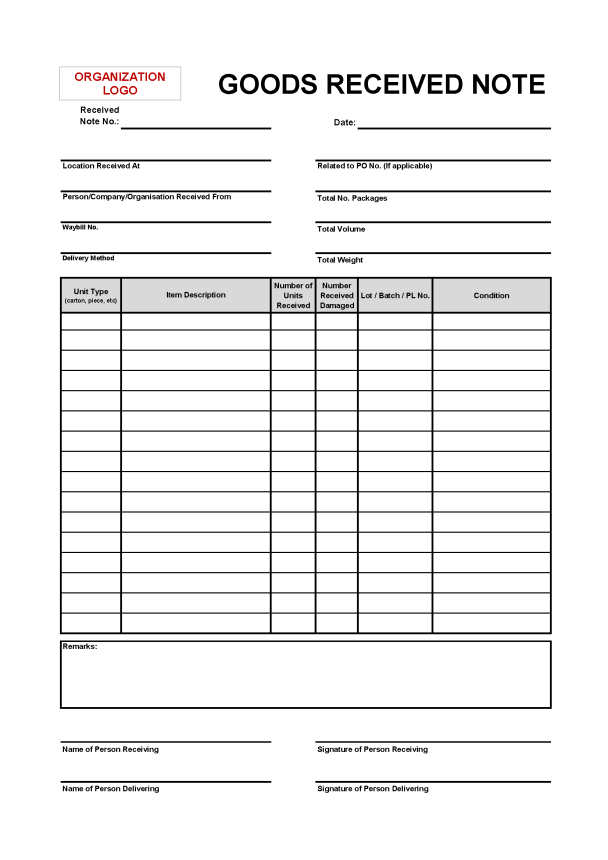

Goods Received Note (GRN) – Some form of GRN is typically generated at the point of reception into a warehouse facility. A GRN will theoretically contain the same information on incoming shipments as a waybill, but a GRN serves a few key functions:

- A GRN may capture information on multiple consignments arriving at once.

- GRNs may take the place of waybills, which may show up with incomplete or incorrect information, or may not come at all.

- GRNs are a form of standardising incoming information in the format most useful to the organisation.

- With proper planning, a GRN can be generated prior to a shipment arrival so warehouse crews know what to expect at the point of offloading.

GRNs should capture dates, locations, persons involved in the transaction and the contents of the cargo entering the warehouse. The exact structure, contents and sequence of a GRN vary depending on needs – as an example, an organisation focused on medical interventions may need to track batch and lot numbers, while an organisation focused on food may choose to track items by the kilogram. Organisations should consider their own internal requirements when drafting a GRN.

Example GRN:

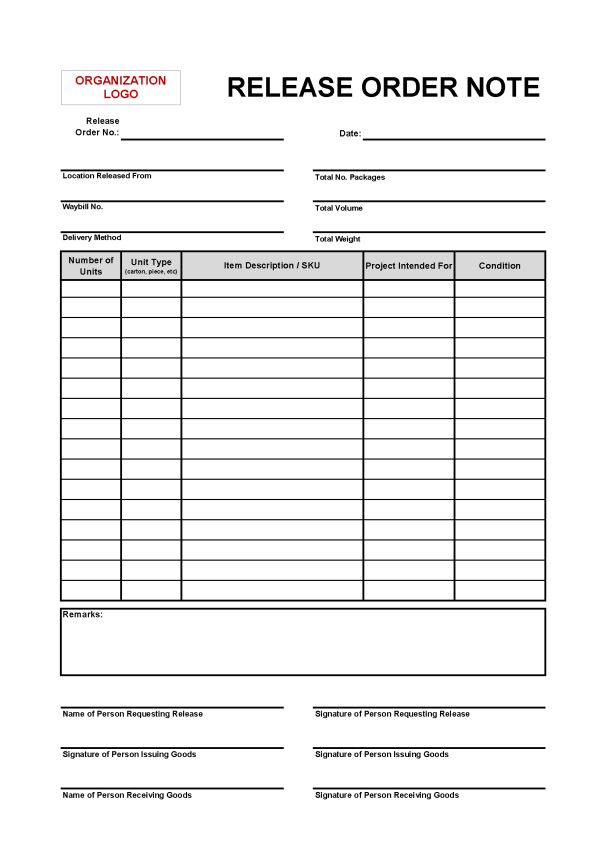

Goods Release Note/Stock Release Order – A goods release note serves a similar function as a GRN, however a release note’s goal is to capture the information on items as they leave the warehouse. Many organisations choose to use the release note the same as an official pick-order; the requesting party initiates the release note indicating which items are required, and obtains counter signature from the appropriate entity within the organisation. A completed release note will capture the final dates, quantities and persons involved with the loading all the way to the truck. A proper release note will tell a story of what was removed, why and by whom. Many agencies don’t actively use release notes, opting to only use waybills at the time of release or communicating pick-orders via email.

Example Release Order:

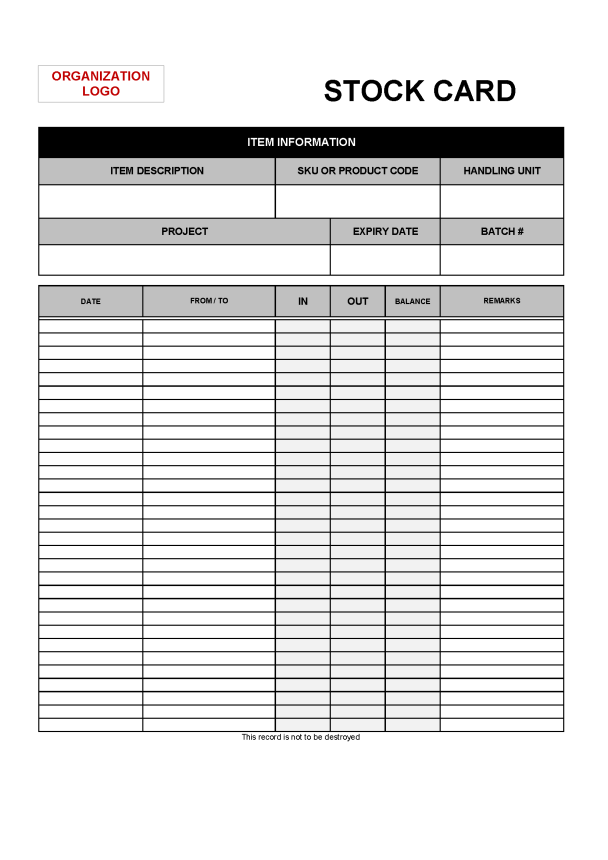

Stock / Stack / Bin Card – A stock card is a physical, hand written record that stays alongside the corresponding physical cargo inside a warehouse or storage facility. Stock cards are sometimes referred to as “stack cards". The nature of the tracking stock card does not change, however – its purpose is to trace the history of the physical consignment in a quick and easy to reference manner.

Example Stock Card:

A stock card should at the bare minimum include:

- The item description.

- Any consignment or procurement relevant information.

- Dates and quantities of cargo items received.

- Dates and quantities of cargo items released.

- Running total balance.

Certain types of goods requiring more meticulous control and analysis, may and need to be tracked using stock cards with specific information, including but not limited to:

- Project or donor earmarks.

- The SKU code (if available).

- Relevant product info - Expiration dates, batch numbers, lot numbers, date of manufacture.

- Reorder threshold.

- Manufacturer references.

- Temperature control requirements.

The stock card has inventory control purposes and is normally managed by the store keeper and updated immediately with each stock movement, including losses. The use of stock cards is imperative in all warehouses, even if the number of articles is short or there is limited rotation. In an ideal context, any warehouse worker on the floor should be able to quickly reference a stock card for the most up to date information on the status and flow that specific good in a warehouse. Quantities and dates on stock card should also match the quantities and dates on a inventory Ledger, GRNs and waybills.

For some items, bin cards can be introduced. These may have a similar format as the stock card but are fixed to the bins or shelves where the items are kept. Bin cards track movements of an item stored in a particular bin, shelf or stack. Bin cards are used when big quantities of the same item are stored, requiring some kind of grouping, easing handling, picking and counting processes.

Inventory Ledger – A inventory Ledger is defined as any system that keeps a running history and current total of all cargo items in a storage facility, as well as all relevant information (expiration dates, donor information, etc). The inventory ledger also tracks inventory transactions (receptions and dispatches) in terms of quantity and value based on the information from the corresponding transaction document. This tool has accounting purposes and is normally managed by an accountancy person and updated in a regular basis (weekly, monthly).